- Home » How Flanging Machines Create Strong, Durable Mattress Borders

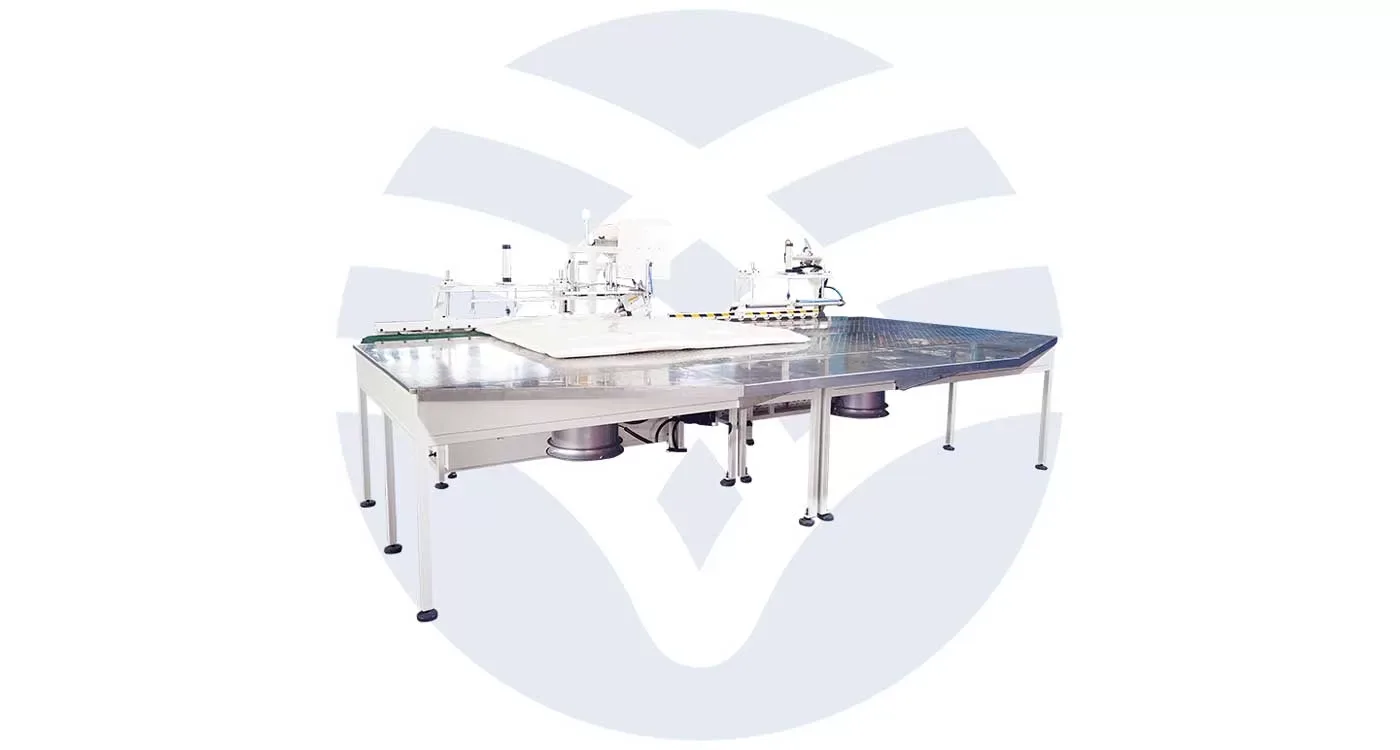

In mattress manufacturing, creating a durable and aesthetically appealing border is essential for both product longevity and consumer satisfaction. One of the most critical tools in this process is the flanging machine. Flanging machines have revolutionized the way mattress borders are made, offering strength, durability, and precision that manual methods simply cannot match. This article delves into how flanging machines work, the benefits they offer, and why they are indispensable in modern mattress production.

The Role of Mattress Borders in Construction

Structural Importance of Mattress Borders

Mattress borders play an important role in both the general makeup and lifespan of a mattress. The border is the outer edge of the mattress and holds the structural support that keeps the internal layers intact. If the border is not done strongly and well, the mattress may lose its shape or sag over time and could even collapse. Comfort level also impacts how sturdy the mattress border is because when that border sags, users often cannot sit or sleep near the edge of the mattress.

Mattress borders have to be able to take a lot of pressure and wear, hence, they are a very important ingredient in the determination of the life of such a product. A flanging machine ensures that these borders are not only handsome but also strong enough to uphold the mattress during its lifetime.

Aesthetic Contribution of Borders

Besides serving a structural purpose, the borders add to the overall aesthetic of the mattress. Many manufacturers use contrasting fabrics or decorative stitching on borders to make them more attractive. The flanging machine helps give clean and precise edges to give a professional and finished look to the mattress, important for customer satisfaction and brand differentiation in a competitive market.

How Flanging Machines Work

Flanging is the process of attaching the border to the top and bottom mattress panels by stitching the three layers together: the border fabric, the quilted panel, and the flange (a fabric extension along the edge of the mattress). A flanging machine automates this process, ensuring consistent and secure stitching across the entire mattress border.

The machine uses a combination of high-tension thread and precision stitching mechanisms to sew through the multiple layers. This strengthens the connection between the border and the mattress panels, ensuring that the entire structure remains intact even after years of use. The machine’s ability to handle different fabric types and thicknesses makes it versatile and effective in creating a durable mattress edge.

Strengthening Mattress Borders

Reinforced Stitching

One of the primary reasons flanging machines can make such strong mattress borders is because of the reinforced stitching they provide. The nature of the flanging process entails a number of thread passes that make for a tight and strong bond between the border fabric and mattress panels. The reinforcement against tearing of the fabric or its separation, even with repeated pressure to sit or lie on the mattress edge, is prevented.

The exact and regular stitching from the flanging machines further minimizes any gaps, weak spots, or uneven tensions that can take away from mattress border integrity. This machine, with its high-tension threads and progressive stitching method, will keep the border attached to the mattress panels for the life of the product.

Managing Different Materials

The modern mattress uses everything from memory foam to latex, cotton, and high-density foam. Each comes in so many thicknesses and types of elasticity for all types of objects, manual stitching is, therefore, extremely challenging. Flanging machines have been designed to handle many fabrics and thicknesses, securing each particular material to the mattress.

This versatility is important during the manufacture of hybrid mattresses, where borders might be needed to hold a number of layers in different densities and textures. Their ability to adapt to other materials ensures that the borders will remain strong and serve their purpose regardless of the makeup of the mattress.

Enhanced Efficiency and Consistency

Automation for Improved Speed

One of the key advantages that flanging machines would have is the element of automation. Where there is manual stitching of borders onto the mattress, it is usually very time-consuming and laborious, hence, there are lots of inconsistencies in quality. A flanging machine would easily do the same process much faster, with little or no mistakes, hence reducing production time without compromising quality.

This increased efficiency allows manufacturers to meet higher production demands and maintain consistent quality across all their mattresses. Since automation reduces human fallibility, manufacturers can mass-produce mattresses that can meet even the highest of standards, every single piece is sure to have a sturdy and robust border.

Consistency in Stitching Quality

The inconsistency in stitching makes points on the border of the mattress weak because, with time, the fabric may separate or fray. It often happens during hand sewing that the smallest change in tension, needle placement, or speed can mean a change in the stitching. A flanging machine ensures that stitch length and tension, and the placement within each mattress, are uniform to create a consistent border, which is durable.

The ability to replicate patterns and stitches on a variety of mattresses with exactness means there is hardly any deviation in quality between one finished product and another. This consistency helps to sustain a manufacturer’s reputation for quality and dependability.

Reducing Waste and Costs

Minimized Material Waste

With manual means of stitching borders, there is typically waste due to improper stitching or incorrect alignment. Flanging machines reduce the material waste factor because they can be assured of accurate stitching on the first pass, reducing any rework or adjustment that is needed, saving materials, and thus reducing production costs in general.

Lower Labor Costs

Automatic border stitching facilitated by a flanging machine significantly reduces labor costs. Fewer workers for the management and operation of the machine are required, and fewer rejections or reworks arising out of human error bring more efficiency and higher profit margins for manufacturers with quality products.

Conclusion

Flanging machines are very important in mattress manufacturing because they ensure the product is sturdy, strong, and reliable with regard to constantly turning out good, high-quality mattress borders. These machines will allow for automation in flanging, thus improving production, they also ensure that mattress borders continue to be solid, attractive, and pleasing during the life of a product. A manufacturer who invests in one of the high-performance flanging machines ensures the durability and attractive look of mattresses since the machines themselves are built to last.

Связанные с ними товары