- Home » How Compression Packaging Works with Modern Mattress Machines

In recent years, compression packaging has revolutionized the mattress industry, enabling mattress manufacturers to produce, transport and sell mattresses more efficiently and cost-effectively. With the rise of online retail and direct-to-consumer mattress brands, modern mattress machines have become a key tool for optimizing the entire supply chain. These machines compress, roll, and pack mattresses in ways that were once unimaginable, providing consumers with the convenience of having a full-size mattress delivered to their doorstep in a small, easy-to-manage box.

This article explores how compression packaging works, the technology behind modern mattress machines, and the impact of this innovation on businesses and consumers.

How Compression Packaging Works

The Mattress Compression Process

The compression of the mattress starts after the complete assembling and quality check of the mattress. Mattress compression machines apply a great force on the mattress, compressing it to a small fraction of its original height. In general, this is done with heavy-duty rollers or plates pressing the mattress from all sides even in order not to damage the internal structure.

After the compression of the mattress, it can either be folded or rolled to further reduce its volume. The most common method applied is rolling, because then one can place the mattress in a much smaller box, making its transportation easier and less expensive. High-density foam mattresses and hybrid mattresses-partly made of memory foam, and partly of springs can be compressed more easily due to their flexible materials.

Vacuum Sealing for Mattress Protection

After being compressed and rolled, the mattress is usually sealed in a plastic bag by using a vacuum so that the mattress keeps its compact shape. This step is crucial to maintain the mattress in the best condition during transportation and storage. The excess air in the packaging is sucked out in the vacuum-sealing process to ensure that the mattress would remain tightly packed and would not rise prematurely.

In addition to the space it saves, vacuum sealing protects the mattress from dust, moisture, and other environmental aspects that may cause damage in transit. The durable plastic bag acts as a sort of protector, keeping the mattress intact right up until it reaches the customer’s home, where the plastic is cut open, allowing the mattress to expand to full size.

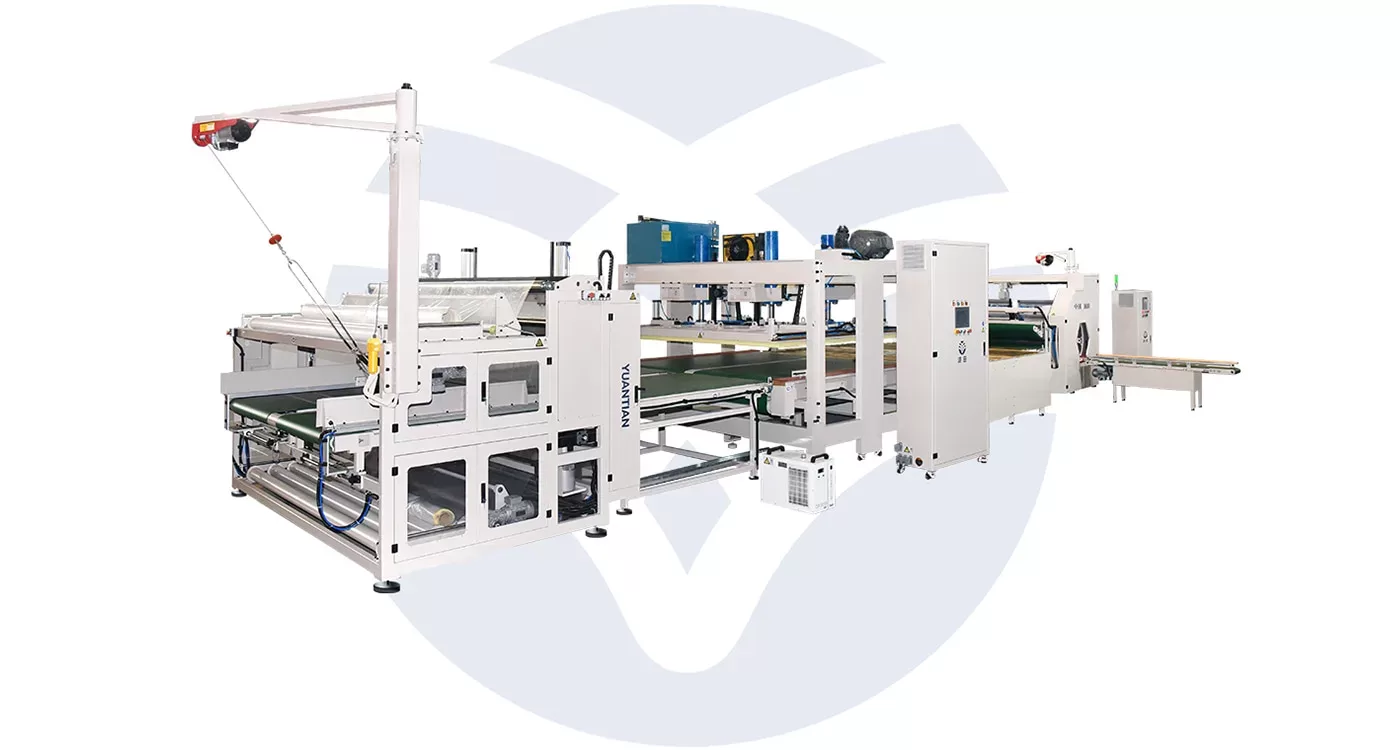

Modern Mattress Machines and Their Role

Types of Compression Machines

There are two primary types of compression machines used in the mattress industry: hydraulic presses and roller presses.

Hydraulic Presses: Hydraulic presses use the pressure of fluids to apply even compression to mattresses. These machines work effectively for thicker mattresses and those with complex interior parts, such as hybrid mattresses containing springs. Hydraulic presses ensure accuracy in that the mattress is compressed without affecting inside materials.

Roller Presses: These are generally used for foam mattresses that are more flexible and easy to compress. The machine pushes the mattress through a set of rollers that flatten and roll the mattress in a compact shape. In general, roller presses are usually quicker and use less energy than hydraulic presses. As such, they are pretty well-liked in high-volume production environments.

Automation and Efficiency

In this regard, most modern mattress machines include advanced automation in place that really simplifies the whole packaging process. Automatic systems can regulate the extent of compression according to the type and size of a mattress. For instance, a setting on the memory foam mattresses differs from that on hybrid mattresses, the former uses a setting that does not tamper with the integrity of the mattress upon compression.

Apart from compression, a lot of machines can easily execute several functions, such as rolling, vacuum sealing, and boxing the mattress in one continuous process. This level of automation frees up the need for heavy labor, speeding up production while minimizing chances of human error, hence assuring better efficiency in operation.

Key Benefits for Manufacturers

The above-mentioned are not the only benefits that come along with the compression packaging of mattresses for their manufacturers. Some other benefits are:

Reduced Shipping Costs: Compressing the mattress to fit into compact packaging, serves to decrease its volume. Hence, it allows the transportation of more units per shipment. It reduces the per-unit cost by so doing, making room for competitive pricing for the consumer.

Storage Optimization: Since compressed mattresses occupy very little space in the warehouse, more inventories can be held without occupying any extra space. This will definitely help reduce storage costs and enhance inventory management in general.

Sustainability: Smaller packaging size translates to less usage of packaging material and less fuel consumption in transportation. This means a smaller carbon footprint-one that also appeals to a fast-growing demand for greener business operations.

Impact on Consumers and the Mattress Market

Convenience of Delivery

One of the most significant benefits of compression packaging for consumers is the convenience it offers. In the past, purchasing a mattress often required arranging for delivery through a moving company, as full-size mattresses were bulky and difficult to transport. Today, thanks to compression packaging, a queen-size mattress can be shipped in a box small enough to be carried by two people or even fit in the trunk of a car.

This has been reflected in the ease with which online mattress sales have steadily grown, enabling consumers to purchase mattresses from their homes and have them conveniently delivered right to their doorsteps. This led many mattress brands to direct-to-consumer models that eschew traditional retail stores for lower prices.

Mattress Recovery and Durability

A common concern of consumers is whether compression affects the durability of the mattress, comfort, among other aspects. However, most new mattresses of today are designed to bear the process of compression without any kind of long-term damage. On opening, the mattress usually requires a few hours to regain its original shape and loft, though some may take about 48 hours to expand fully.

Because of that, the manufacturer uses foam and spring materials that are resistant to compression so that afterward when it is unbucked, the mattress is going to perform as it should. In addition, most mattresses sold in compressed form have extended warranties, which assure durable life for the product.

Conclusion

Compression packaging, powered by modern mattress machines, has transformed the mattress industry by making production, storage, and shipping more efficient. This technology has enabled the growth of direct-to-consumer mattress brands, reshaping the way consumers shop for mattresses and making it more convenient than ever to have a high-quality mattress delivered right to their door.

As the demand for convenience and sustainability continues to grow, advancements in compression technology are likely to push the boundaries even further, offering even more innovative ways to package and deliver mattresses.

Связанные с ними товары