- Home » How Automation Has Reduced Production Costs in the Mattress Industry

Automation has highly revolutionized the mattress industry over recent decades from manual, labor-intensive manufacturing to sophisticated and highly effective systems. With automation, manufacturers are now able to increase productivity, cut errors, and lower production costs, which has been a vital key. In an increasingly competitive marketplace, such cost savings allow mattress companies to realize a profit even while offering good-quality products to consumers.

The Rise of Automation in Mattress Manufacturing

Traditional manufacturing of mattresses is one of the most labor-intensive tasks because skilled laborers are required to combine components and sew fabrics while also manually performing difficult patterns of quilting. While these methods ensure a personal touch, they take much time and are often prone to human error. To keep up with the demand for low-cost, high-quality mattresses, manufacturers began to look elsewhere to scale production without sacrificing quality.

The mattress industry has been revolutionized since the introduction of automated machinery. Over the years, more and more technologies that were able to handle multi-stages in the mattress production line, such as fabric and foam cutting, component assembling, and finished product packaging, continued to be put into place by manufacturers. Nowadays, automation has a considerable share in the production of mattresses, which greatly reduces the amount of human labor involved while increasing the quantity and reproducibility of mattresses.

How Automation Reduces Production Costs

Labor Cost Reduction

The reduction in cost due to labor is one of the most direct and profound ways automation has helped reduce production costs in the mattress industry. Traditional manufacturing requires a substantial workforce to deal with each particular stage of production, from cutting materials to sewing fabrics to assembling layers. Each step requires a significant amount of labor costs, including workers’ wages, training, and benefits.

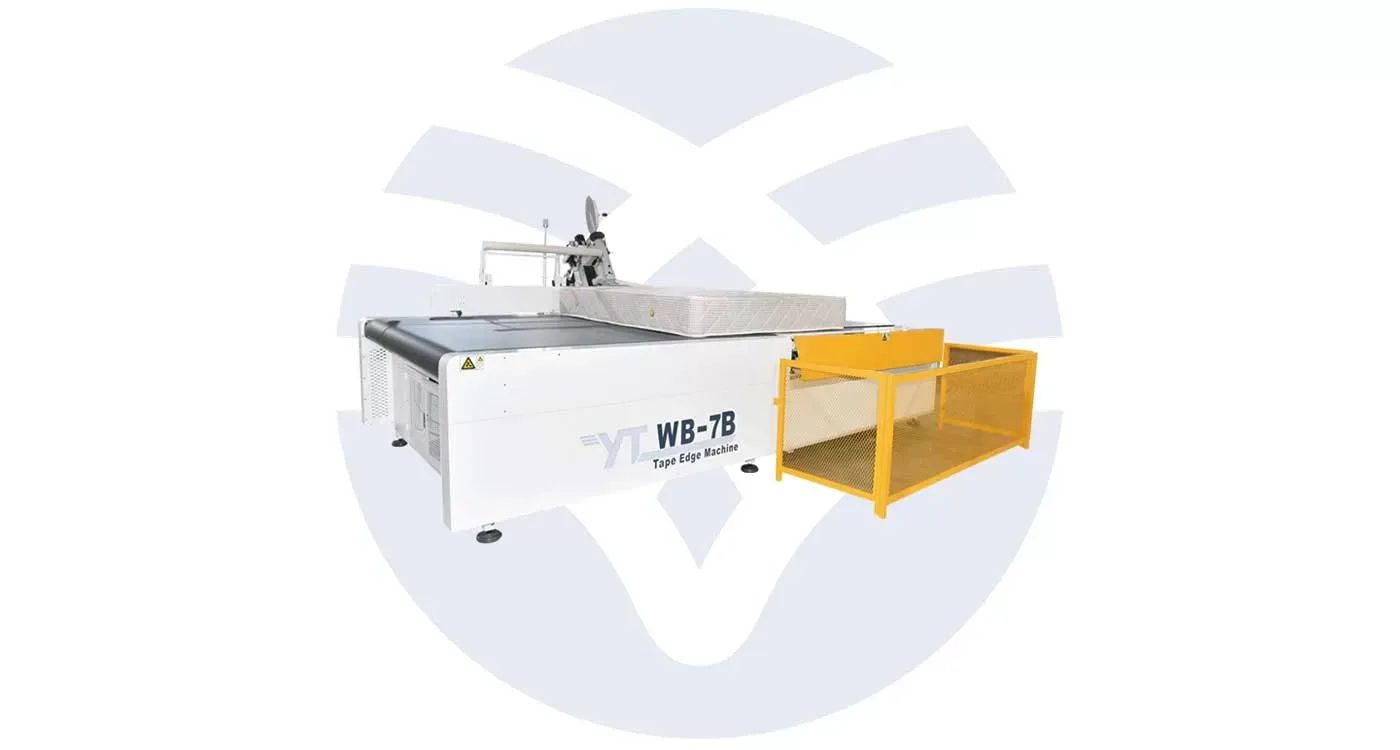

Automation streamlines these processes, allowing the machines to take over the heavy workloads left originally to humans. As an example, quilting machines sew mattress covers automatically. These machines can do this work at far greater speed and with far greater accuracy than any human could ever hope to achieve. Because of this fact, the manufacturer is able to either reduce their workforce or shift labor to higher-value applications, thus lowering the overall cost of labor.

Increased Production Speed

Apart from the cost of labor that is saved, automation has truly quickened mattress production. Running an automated system all day produces more mattresses in a shorter period than manual means. Machines don’t take breaks and can work at very consistent speeds without fatigue or error.

This directly corresponds to increased production speed, translating into cost savings. The faster manufacturers can make mattresses, the more they are able to leverage economies of scale by spreading fixed costs such as rent, utilities, and equipment over more units of a product. Because of this, the cost per unit of producing a mattress goes down, allowing manufacturers to offer competitive pricing without eating into profitability.

Reduction in Material Waste

Automation reduces material waste, hence reducing production costs. Traditionally, mattress manufacturing involved several manual cutting jobs related to fabrics and foams, which often resulted in inaccuracies and errors. Material waste not only increased material costs but also reduced profitability.

With the development of automated machines that can do the cutting, most of these challenges have all but disappeared. For instance, CNC cutters are programmed to cut materials to exact dimensions so that each piece is exactly the size and shape desired. Often, the patterns are laid out in such a manner as to minimize waste. This in turn cuts down on the amount of material that is wasted and reduces the raw-material cost, thereby enhancing the sustainability of the production processes of manufacturers.

Improved Product Consistency and Quality

Automation has also ensured much-improved consistency of products and quality, further helping to cut down production costs. In the manufacturing of mattresses by hand, differences in craftsmanship can bring about variations in the final product. For example, inconsistent stitching, misplaced layers, or wrongly coiled springs are all defects in mattresses that may require repair or even rejection, adding to the cost.

On the other hand, automated machines are programmed in a way that the tasks are carried out with immense precision, making the mattresses consistent and qualitative every time they are produced. Consistency reduces the number of defective products, thereby enhancing the reputation of mattress manufacturers, resulting in fewer returns, warranty claims, and customer complaints. By reducing these costs involving defective products, manufacturers can further lower their overall production expenses.

The Long-Term Financial Benefits of Automation

Lower Maintenance and Operating Costs

While the initial investment in automation technology can be huge, benefits in cost start to amass over time. The machines are designed to be efficient and durable, in most cases, little maintenance and upkeep are required. Modern machines often have diagnostic tools that can help them detect problems that can be dealt with before they become costly, enabling manufacturers to undertake corrective actions.

Also, most mechanized systems tend to use energy more efficiently than manual modes of production. Therefore, utility bills are more manageable and the environmental impact is less detrimental. From an energy consumption cost perspective, the efficiency in running the machinery could present mattress manufacturers with a better cost-cutting solution.

Scalability and Flexibility

Automation of processes has made it rather easy for mattress manufacturers to scale their operations. In other words, through automated systems, manufacturing companies can quickly scale up production levels in response to growing demand without necessarily investing in expensive infrastructure and hiring more people. Such scalability in business allows companies to follow market trends and seize growth opportunities with little additional cost.

Automation has facilitated greater flexibility in mattress design. For instance, state-of-the-art machinery today can quickly retool to accommodate various designs and sizes, apart from different materials. Manufacturers can thus provide a broader range to the consumer without going through hectic retooling or downtimes in production. The resultant flexibility therefore translates into cost economies by negating the need to duplicate production lines and specialized equipment.

Enhanced Profit Margins

Cost reductions from automation will directly translate into higher profit margins for mattress manufacturers. In other words, lower labor costs, reduced material waste, increased speeds of production, and overall higher-quality products make the manufacturing process rather more efficient and cost-effective. With these lower production costs, it is possible to pass on savings to the consumers with the lower prices or to keep them through higher profit margins by the manufacturer, thus allowing further competitiveness.

The Impact on Consumers and the Mattress Industry

Affordable High-Quality Mattresses

Probably the most important dividend of automation in mattress manufacturing is that it has made high-quality mattresses more affordable to consumers. With lesser production costs, manufacturers can charge less for their products, with all the premium features included, such as advanced innerspring systems, layers of memory foam, and lavish quilting.

Such democratization of quality mattresses implies a wider circle of consumers who can enjoy comfort, support, and durability that used to be possible only with very expensive beds.

Increased Competition and Innovation

Automation cost savings also have fomented competition and innovation in the mattress industry. As manufacturers seek ways to cut costs, they are in a position to invest in research and development, leading to the development of new materials, designs, and technologies.

This has led to the wide variety of mattress options available to consumers, including eco-friendly products and mattresses that boast smart technology features such as adjustable firmness and sleep tracking.

Environmental Benefits

Apart from the cost benefits, automation has contributed a great deal to greener manufacturing practices. With reduced material waste and lower energy consumption, automation has helped mattress manufacturers minimize their environmental footprint. This becomes important in industries traditionally relying on synthetic materials and energy-intensive processes to produce goods.

Automation enhances this by manufacturing mattresses at increased rates while reducing the carbon footprint selling point very attractive to environmentally sensitive consumers.

Conclusion

Automation has been a driving force behind the reduction of production costs in the mattress industry, allowing manufacturers to produce high-quality products more efficiently and at a lower cost. By streamlining labor, reducing material waste, increasing production speed, and improving product consistency, automation has reshaped the industry, benefiting both manufacturers and consumers. As automation technology continues to evolve, the mattress industry will likely see even more innovation, cost savings, and sustainability improvements in the years to come.

Связанные с ними товары