- Home » Harnessing Technology: The Future of Customization in Mattress Machinery

In the rapidly evolving mattress manufacturing industry, customization has emerged as a key trend driven by consumer demand for personalized sleep solutions. As consumers are getting more demanding and the market turns intensely competitive, manufacturers are reaching out to advanced technologies that allow more flexibility in mattress production.

The future of mattress machinery will have to combine the ability to adapt to these demands by efficiently and cost-effectively letting manufacturers come up with products that are tailored to customers’ needs. This paper considers how technology is changing customization in mattress machinery and what the future holds for this dynamic industry.

The Rise of Customization in Mattress Manufacturing

Changing Consumer Preferences

Modern consumers are more aware and choosy with the products they buy. They look for products that best suit their needs, even in mattresses. People consider things like sleep position, body weight, health conditions, and comfort preferences.

In this respect, the need for mattresses that provide customized support, firmness, and materials has rapidly increased, therefore compelling manufacturers to innovate to suit such diversified needs.

The Competitive Landscape

With rising competition in the mattress industry, the few brands that manage to offer personalized products will stand out in the market. Customization allows a manufacturer to create a product for which there can be no direct comparison, thereby gaining a differentiated status.

Customization builds a competitive advantage in an industry with a lot of choices for consumers and in which they can compare the products online. Quick delivery of customized mattresses at an affordable price is fast becoming the determining factor.

Advances in Mattress Machinery for Customization

Automation and Robotics in Production

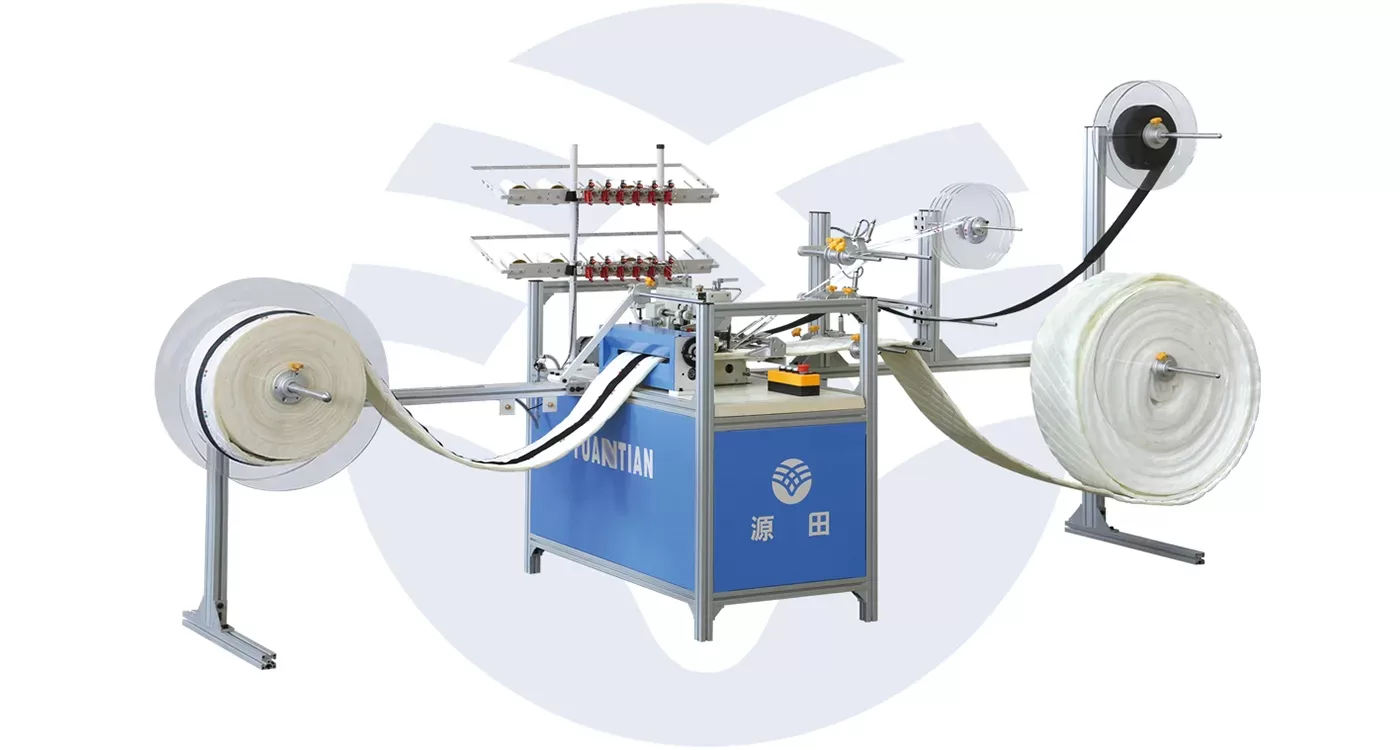

The innovation of mattress machinery today is being driven by automation and robotics, which make the possibility of producing customized mattresses with high precision and efficiency possible for a manufacturer. Such technologies automate cutting machines that can cut mattress layers to specification, hence allowing customization by size, shape, and material makeup.

Layering, stitching, and assembling are tasks carried out by robotics quickly and accurately, hence meeting the exact requirements of the customer for every mattress produced.

CNC Machining for Precision and Flexibility

The other technological advancement at the core of customization in mattress manufacturing lies within CNC machining. Essentially, CNC machines are a workmanship of computerized controls that manage tools and machinery with high precision. The application of CNC machines involves cutting and shaping foam, springs, and other materials with exacting accuracies for the production of mattresses.

Using this technology, mattress makers can now mass-produce special designs and features, like zoned support or contoured surfaces, tailored to individual needs.

Integration of Smart Technology

Sensing and IoT devices, if integrated with mattress machinery, can pick up data on a range of variables such as temperature, pressure, and material properties during their time of production. This can be further exploited in order to optimize the process of its manufacture in real-time and ensure that every mattress is made to specification.

Furthermore, smart technology is capable of developing adjustable mattresses that the consumers can adjust even after the purchase. This provides a high degree of personalization.

Benefits of Customization in Mattress Machinery

Increased Customer Satisfaction

One of the major advantages of customization is increased customer satisfaction. Consumers who are allowed to opt for a mattress that is aligned with their requirements have greater chances of being satisfied with the purchase.

This satisfaction leads to increased customer loyalty and positive word-of-mouth, very critical for business growth in a competitive market. Customization would also empower the manufacturers to produce for niche markets, such as those with special health or sleep-related needs, improving their customer satisfaction.

Enhanced Operational Efficiency

Customization, if supported by proper technology, also brings in operational efficiency improvements. Automated and computerized systems bring down errors to near zero so that every mattress that goes out from the production line is made to the very specifications required. This allows for the reduction of possibilities of waste and rework, thereby time and resources are saved.

With the ability to make customized mattresses on-demand, there is no need to carry large inventories, thus freeing space and capital to be used elsewhere in the business.

Market Differentiation and Branding

Differentiation in a crowded marketplace is very clear. Customization helps mattress manufacturers create a truly unique product that defines them and gives shape to the identity and values of their brand.

This differentiation can turn out to be very powerful from a marketing perspective in drawing a certain target audience and building a strong brand reputation. Moreover, a high degree of customization portrays the brand as being innovative and customer-driven, two ideals that are cherished by modern consumers.

Challenges and Solutions in Customization

Balancing Customization with Cost

One of the major challenges concerning the provision of customized products to customers is managing costs. This generally involves much more complex machinery, special materials, and extra workers, factors that increase production costs.

However, with advances in technology, especially in automation and mass customization, these costs can be reduced. Manufacturers are now able to produce customized products at competitive prices without sacrificing quality by optimizing production and eliminating waste.

Managing Supply Chain Complexity

Customization makes a supply chain complicated because manufacturers are forced to deal with an increased variety of materials and components. This raised complexity could mean that lead times become longer, with an increased chance of the occurrence of supply chain perturbations.

To avert these challenges, many manufacturing companies are applying strategies such as just-in-time inventory management systems and closer involvement with their suppliers. Technology is also doing its part, superior software solutions can make the process of supply chain operations easier and provide an assurance of material availability when needed.

Ensuring Consistent Quality

The same quality achieved in the production of customized products cannot be consistently achieved, especially at scale. Inconsistencies could originate in material or process variability, thereby impacting the end product.

In this regard, manufacturers are investing in technologies for quality control, automated inspection systems and real-time monitoring, to make sure that each mattress meets predetermined standards, irrespective of the level of customization involved.

The Future of Customization in Mattress Machinery

Continued Technological Advancements

More technological innovation shall be the future of customization with mattress machinery. Particularly relating to artificial intelligence, machine learning, and robotics, we will have even better solutions offering very high levels of customization efficiency in the future.

If technology advanced further, extreme personalization could be expected, whereby mattresses are tailored to a person’s needs in a way one cannot even imagine today.

Sustainability and Customization

Sustainability is another factor that is going to only continue playing a bigger role in the future of customization. More consumers than ever before are paying attention to the environment, so manufacturers will have to adapt to offer more eco-friendly customization options.

This could be through the use of sustainable materials and energy efficiency in the production process, along with recycling programs that would allow consumers to customize their mattresses in such a way as to be consistent with their environmentally friendly values.

Conclusion

With new technologies, this machinery and the future of customization in the mattress industry were on an upswing, allowing manufacturers to produce at scale an incredibly personalized product. As consumers begin to want more tailored sleep solutions, the pathways to the top will be clear for those manufacturers who embrace such technologies in an increasingly competitive environment.

By being focused on innovation, efficiency, and sustainability, the mattress industry will be able to utilize this immense power tool of customization to create products that enable the fulfillment of various customer needs.

Связанные с ними товары