- Home » Factors Influencing the Speed of Mattress Flanging Machines

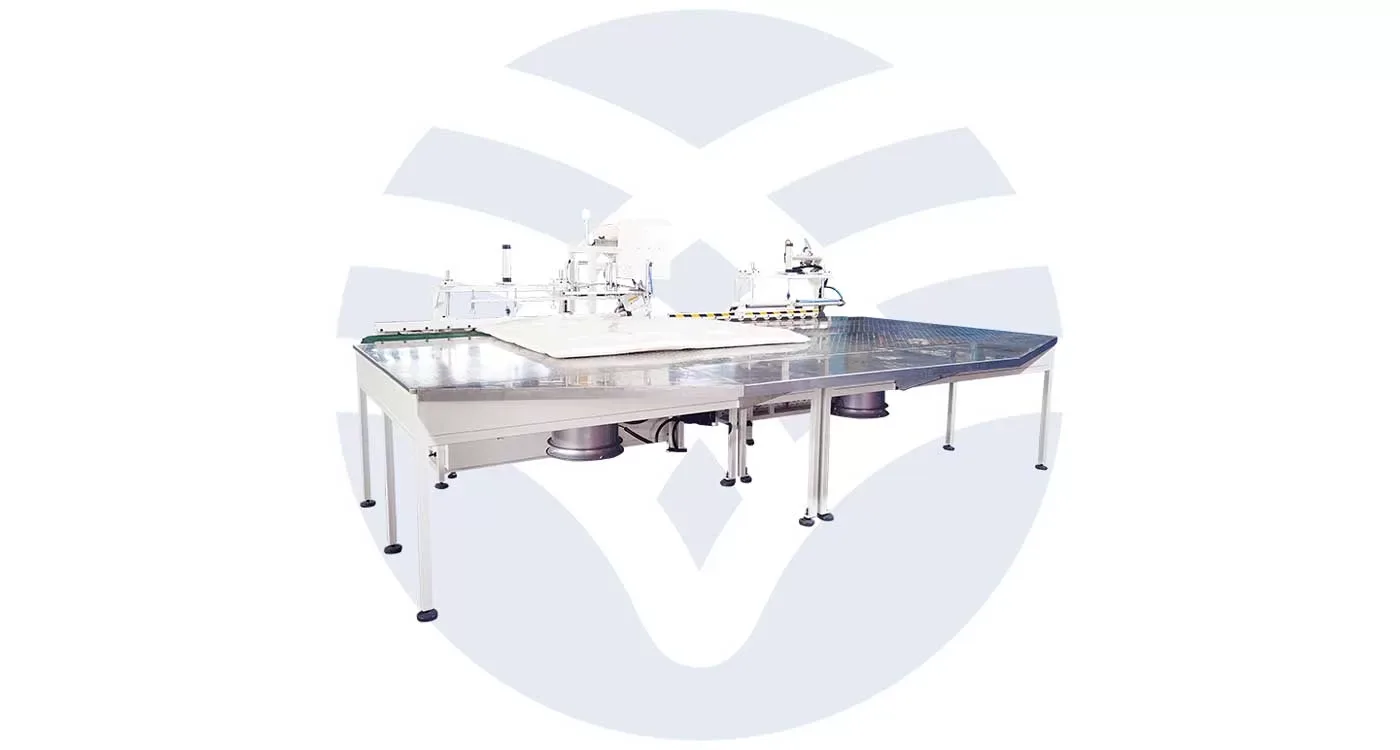

Mattress flanging machines play a very important part in the mattress manufacturing process because these are the machines that sew together the top and bottom panels with the border material. These machines are designed for operating at high speeds because high-scale production commands high speeds. However, various factors apply depending on the speed at which these machines can operate.

In fact, learning them will equip the manufacturers to take their processes to the next level as far as productivity and costs of production are concerned. Some key factors that determine the operating speed of mattress flanging machines include machine design, skilled expertise by operators, properties of materials handled, and maintenance practices.

Machine Design

Automation and Technology

One very important factor of a mattress flanging machine that influences its speed is the level of automation. Advanced technologies such as CNC on new flanging machines have enabled better stitch control and, therefore, a higher level of accuracy. Automated machines can run faster and with greater consistency than manual ones due to a lack of human error in operation. More so, features such as automatic thread trimming and material feed systems increase speed by reducing downtime between operations.

Apart from automation, the addition of sensors and feedback further optimizes a machine’s performance. For instance, thickness-detecting sensors regulate stitch speed to produce stitches of uniform quality at the maximum speed possible. Advanced technological machines typical of those in most modern-day industries also tend to execute operations much faster and quicker compared to older, less technologically advanced ones.

Machine Size and Configuration

The size and configuration of the machine, too, play a role in determining speed. Larger machines with more robust components can work at much higher speeds since they will be designed to cope with the resultant high mechanical stresses due to rapid movement. Machines with arrangements for multiple stitching heads or dual needles can execute flanging operations at faster rates by facilitating parallel processing of tasks.

Some of the machines in mattress flanging have been designed to incorporate modular configurations whereby the different parts of the machine can be varied or adjusted depending on specific production needs. Such modular designs allow manufacturers to optimize the machines for speed, particularly when manufacturing various types or sizes of mattresses.

Motor Power and Drive System

The other factors that relate directly to the speed at which a flanging machine can run are the power of the motor and the efficiency of the drive system. Higher-powered motors have more torque to apply to the needle and feed mechanisms, allowing the sewing to be faster without slowing down, even when sewing thicker materials. The drive systems on some machines, such as servo motors, may be designed in such a way as to offer more speed control and quicker response times compared to a traditional mechanical drive system.

Operator Skill and Experience

Training and Expertise

Even for the most modern machinery, mattress flanging speed is many times controlled by a number of skill factors of the operator. The experienced operators manage to perform the work in a shorter time by properly setting up the machine, quickly making adjustments during the production process, and troubleshooting problems as they arise. Inexperienced operators may have difficulties with machine settings or they identify problems later and subsequently correct them, which makes their production time longer.

Operators must also be cognizant of the specific needs of different types of mattresses. For example, it may well be the case that an operator using a flanging machine would need to adjust either the tension, stitch length, or speed for a foam, innerspring, or hybrid mattress. The advantages accruing here are that the operators will be acquainted with making such adjustments quickly and accurately without needing to resort to some trial-and-error procedures, which unfortunately will slow production down.

Workflow Optimization

Good workflow and operators help to create many efficiencies in mattress flanging overall. A good operator manages materials, prepares materials in advance, and knows how to handle workpieces from one processing stage to another. They reduce all the other incidents that involve spending time reloading material, adjusting machines, and repositioning parts. Smoothening the workflow with fewer interruptions provides an opportunity for flanging machines to work at maximum continuous speed by increasing productivity.

Material Properties

Fabric and Border Material

The characteristics of the fabric and border material being sewn together in the flanging process also affect the machine speed. The thicker or denser materials, like heavy-duty quilting or multi-layered foam, would require much slower stitching speeds in order to create accurate and durable seams. On the opposite side, lighter material, like thin fabric or nonwoven textiles have higher stitching speeds since such materials don’t stress the needle and feed mechanisms as much.

Other factors that come into play include the material’s tendency to stretch or its elasticity. Materials with a high degree of elasticity will have to be subjected to special treatments to avoid puckering or distortion, which again slows down the flanging process. Machines equipped with variable speed drives or differential feeding mechanisms are better equipped to handle such materials without sacrificing speed.

Thread Quality and Thickness

Thread types can have an effect on the speed and quality of stitching during the flanging process. Generally speaking, the heavier threads require a slower machine speed to keep from breaking or damaging a needle. Likewise, poor-quality threads that tend to break easily may force operators to run machines at a slower speed in order to avoid thread breakage and result in lost time in re-threading.

The threads should be of high quality and of such type that is suitable for high-speed sewing to achieve the best performance of the machine. Generally, threads having higher strength, flexibility, and friction resistance allow for higher machine speeds with less deterioration in seam quality.

Maintenance and Machine Condition

Regular Maintenance

Because proper maintenance is key to the continuous peak operation of mattress flanging machines, poor maintenance tends to show up in things like needle wear, misaligned components, and lubrication issues that reduce the speed and quality of stitching. This helps prevent unnecessary stoppages in the process. Schedules for preventative maintenance, including routine inspections, cleaning, lubrication, and part replacements, will help the machine run as smoothly as possible at optimal speeds.

Operators are also supposed to pay close attention to the performance of machines to maximize their service life by spotting problems well in advance of their causing breakdowns. A slight loss in stitching speed, an increase in noise, or a slight unevenness in the stitch may suggest that the machine requires servicing or adjustment. Early remedies will prevent further deterioration or reduce downtime.

Wear and Tear

Like any mechanical equipment, mattress flanging machines may deteriorate over time. The needles, belts, and bearings will wear out, and the efficiency or speed of the machine may decline accordingly. Nonetheless, wear and tear can be greatly minimized by using high-quality replacement parts and maintaining a proper maintenance log so that the machine will work continuously at high speeds.

Besides routine maintenance, the upgrading of older machines with modern components such as energy-efficient motors or better control systems can also extend their useful lives and enhance their performance. In fact, such upgrades can make the operations of older machines at par with more recent models in terms of speed and efficiency.

External Environmental Factors

Temperature and Humidity

The working environment can also influence the speed and performance of the mattress flanging machine. For example, high humidity might make certain materials absorb a lot from the air, which then would become difficult to handle or sew, thus slowing down the flanging process as the machine has to reduce speed in order not to develop anomalies like fabric distortions or thread breakages.

Similarly, very high and low temperatures would influence the functioning of the parts of the machine. During extremely hot conditions, the machine might risk overheating, and thus the operators would have to lighten off speed or make frequent stops to allow it to cool down. Conversely, when the temperature was too cold, lubrication became thicker and thus caused friction, slowing down the movement of the machine.

Power Supply

Speed can also be affected by the stability and quality of the power supply. Machines experiencing fluctuations in power or low voltage are often unable to maintain speed consistently because the motor is not able to get the energy required for running. One should ensure a stable power supply, and use surge protectors or voltage regulators, among other ways, to maintain the machines at their best performance.

Conclusion

Besides, the operating speed of mattress flanging machines is dominated by different reasons: machine design, operator capability, material properties, maintenance habits, and external conditions. All these factors, if understood, would enable manufacturers to analyze the best practices for flanging, raise productivity, and lower costs.

These strategies involve investments in state-of-the-art and automated machinery, proper training of personnel, and a systematic schedule for maintenance that ensures the maximum speed and efficiency of mattress flanging machines.

Связанные с ними товары