- Home » Exploring the Latest Advancements in Mattress Flanging Technology

Mattress manufacturing has seen significant advancements over the years, with flanging technology playing a crucial role in the industry. Flanging is a process that attaches the border material to the mattress top and bottom panels, creating a neat, finished edge.

This article delves into the latest advancements in mattress flanging technology, exploring how these innovations are improving production efficiency, product quality, and overall consumer satisfaction.

Understanding Mattress Flanging

What is Mattress Flanging?

Mattress flanging refers to an integral process in mattress manufacturing whereby a top and bottom panel is sewn to the border material. These create strong edges and, at the same time, aesthetically pleasing edges that help improve structure and raise the overall look of the mattress. Traditionally, flanging was done by hand and required highly skilled labor and much time.

Importance of Flanging in Mattress Manufacturing

Flanging is a process that binds the mattress edges tightly to ensure that the shifting of layers is completely avoided and the mattress gets back to its original shape. This brings immense durability and comfort, thus, this critical step of mattress making assures the mattress of long life and comfort.

Recent Innovations in Mattress Flanging Technology

Automated Flanging Machines

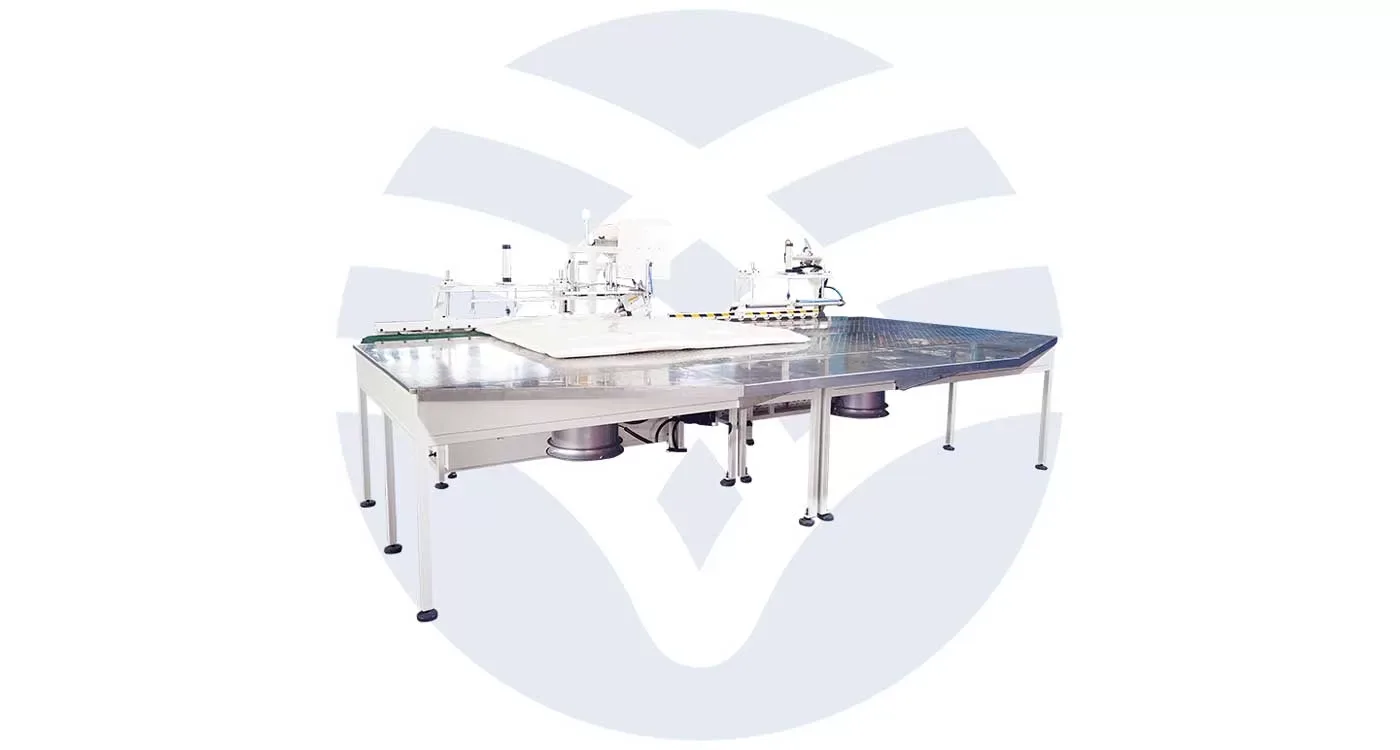

Probably, the finest invention of mattress flanging technology is an automated flanging machine. This has transformed the entire manufacturing process with a drastic reduction in manual labor demand and, at the same time, increasing the speed of production.

Benefits of Automation

The automated flanging machines come with a host of benefits, which are as follows:

- Increased Production Speed: Automation permits faster cycles of production to meet increasing demand for mattresses in the market without any sacrifice on the quality front.

- Consistency and Precision: Automated machines ensure consistent stitching quality, eliminating human error and further enhancing durability in mattresses.

- Cost Efficiency: A reduction in labor costs with an increased production efficiency allows manufacturers to save significantly on costs, which can be passed on to the consumer.

Advanced Sewing Technologies

Advanced sewing technologies in modern flanging machines enhance the quality and strength of stitches. Programmable stitching patterns and high-speed sewing capabilities ensure attaching the flanges with a lot of precision and strength.

Programmable Stitching Patterns

Programmable stitching patterns allow manufacturers to flange differently according to various mattress designs and materials. This flexibility makes the production of various mattress styles possible and satisfies different consumer preferences.

High-Speed Sewing Capabilities

Inbuilt high-speed sewing capability improves production efficiency by lots, reducing the time taken in every flanging operation. This will not only increase productivity but also allow making more deadlines and fulfilling larger orders without letting go of the quality.

Enhancements in Material Handling and Feeding Systems

Integrated Material Handling

Most of the modern flanging machines are integrated with material handling systems. These systems aid in the feeding of mattress panels and border materials to be interlocked or flanged. These systems provide for smooth, continuous feeding of material to flanging machines, thereby minimizing downtime and increasing overall efficiency in production.

Automated Feeding Systems

Automated feeding systems eliminate most of the manual intervention required during the flanging process. This system properly positions the materials, which allows for very precise alignment and consistent stitching, hence a high-quality finish. This is achieved with minimal manual adjustments.

Quality Control and Inspection Technologies

Real-Time Monitoring and Adjustments

These latest flanging machines come with real-time monitoring and adjustment features. With continuous vigil on the stitching process, a system that makes out deviations/defects makes immediate adjustments to keep the quality of stitching high and thus makes every mattress meet strict parameters.

Enhanced Inspection Systems

Advanced inspection systems, such as vision systems and sensors, are now being incorporated into flanging machines. These carry out fine inspections on the flanges for any inconsistencies or defects. This proactive approach to quality control will ensure that only those flawless mattresses move to the next production process.

Ergonomic and Safety Improvements

Operator-Friendly Designs

Modern flanging machines have been designed with ergonomics in mind, much attention has been paid to operator comfort and safety. These features include adjustable workstations, more intuitive controls, and reduced noise levels for a more pleasant working environment, increasing productivity while reducing the potential for work-related injuries.

Safety Features

Most of the advanced flanging machines of this time are incorporated with safety features like an emergency button, safety guards, and automatic shutdown of the machine. These protect operators from the possible risks involved and provide operators with a safe environment and efficient working.

Integration with Smart Manufacturing Systems

Internet of Things (IoT) Integration

IoT technology integrated into flanging machines provides inter-system communication with different manufacturing systems. The given connectivity allows the transfer of information in real time, thus supporting remote monitoring and predictive maintenance in order to optimize the whole production process.

Data Analytics and Predictive Maintenance

In the modern flanging of mattresses, technologies for data analytics and predictive maintenance are of paramount importance. The analysis of machine performance data can identify impending issues before they cause downtime. Schedules of predictive maintenance can be put in place, greatly reducing unexpected breakdowns and extending the life of the equipment.

Future Trends in Mattress Flanging Technology

Sustainable Practices

In the future, flanging technology in mattresses will be based on sustainability. Developments like eco-friendly material sources, energy-efficient machinery, and waste reduction techniques will play a huge role as industries turn to minimize impacts on the environment.

Enhanced Customization Options

Advancements related to flanging technology will further support higher levels of customization, enabling manufacturers to produce mattresses that meet specified consumer needs. This would also involve the easy changeover to various stitching patterns, materials, and mattress designs to suit diversified tastes.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning are the future drivers of mattress flanging technology. These technologies will further bring precision and efficiency to the flanging process by learning from the data and continually optimizing the machines’ performance.

Conclusion

The latest advancements in mattress flanging technology are transforming the mattress manufacturing industry. Automated flanging machines, advanced sewing technologies, enhanced material handling systems, and improved quality control measures are revolutionizing the production process.

These innovations not only increase efficiency and reduce costs but also improve the quality and durability of the final product. As technology continues to evolve, the future of mattress flanging promises even greater advancements, driving the industry towards more sustainable, efficient, and customized manufacturing practices.

Связанные с ними товары