- Home » Essential Guide to Tape Edge Machinery for the Mattress Industry

In the mattress industry, quality and efficiency are key. Tape edge machinery plays an essential role in this by ensuring mattresses are neatly sewn and uniformly edged.

For mattress manufacturers, choosing the right tape edge machine and understanding its operation, maintenance, and advancements is crucial for producing high-quality products and optimizing production processes. This guide will explore the fundamental aspects of tape edge machinery, covering its features, types, benefits, maintenance needs, and the latest technological advancements.

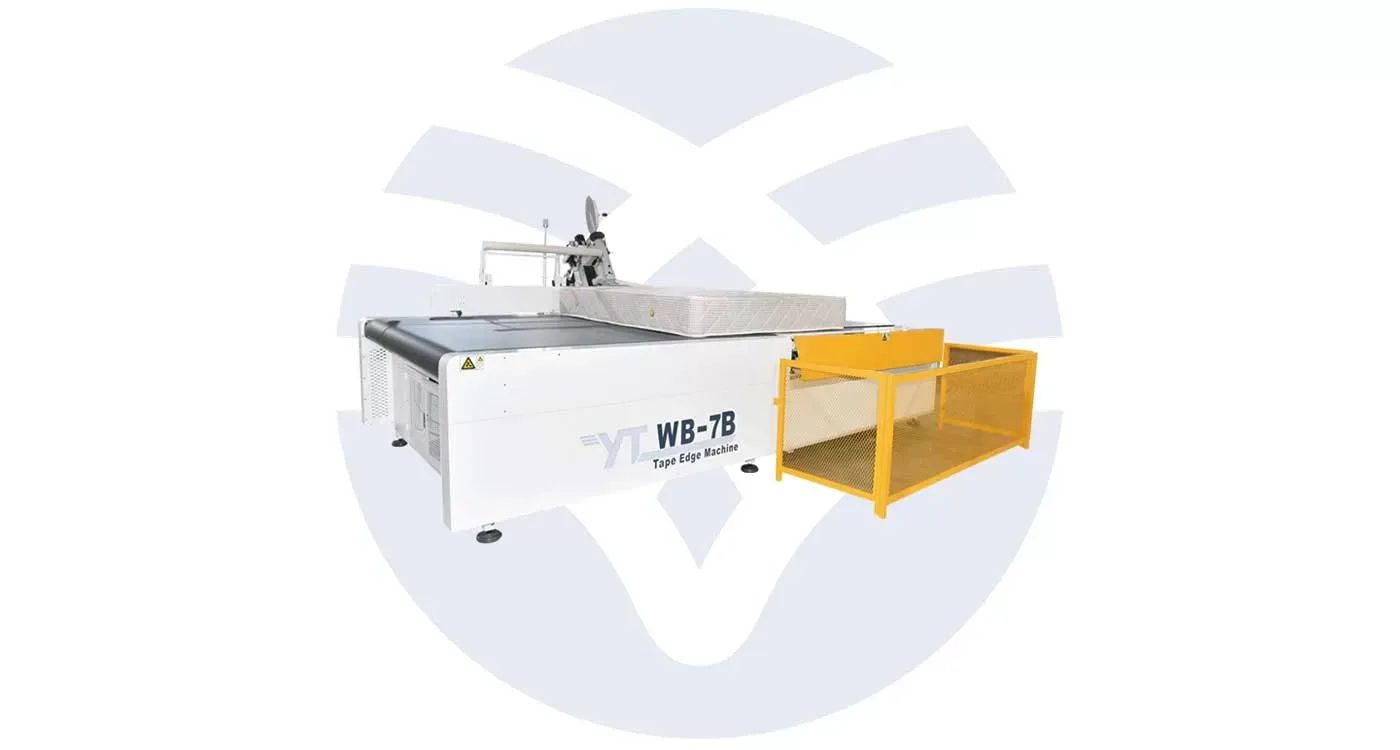

What is Tape Edge Machinery?

Tape edge machines are special sewing machines designed to give a finish to mattress edges by sewing on fabric or tape along its borders. This gives the mattress a neat, professional appearance and seals the layers so that they do not shift.

Unlike the average sewing machines, tape edge machines differ in the interior mechanisms allowing them to accommodate mattress bulk and weight. This forms an indispensable component in every mattress line, adding so much to the aesthetic and durability aspects of the mattress product.

Importance in the Mattress Manufacturing Process

In the manufacture of mattresses, much attention is given to the finishing of edges, since it is that important aspect dictating the appearance and bringing structural integrity to the product. Tape edge machinery ensures all layers in the mattress are retained intact, securing the edges against fraying and dislodging over time.

Good-quality edging is a means to prevent shifting inside the mattress as comfort and life variations occur. With a good tape edge machine, producers achieve better quality and brand reliability.

Types of Tape Edge Machines

Many types of tape edge machines have been developed and derived for a number of different purposes in production. Understanding these types will help a manufacturer make relevant decisions based on specific needs, budget, and the scale of production.

Manual Tape Edge Machines

Manual tape edge machines rely on plenty of operator involvement to feed the mattress through the stitching process. These models are more labor intensive and slower than their automatic cousins, but do find a niche in small-scale operations or custom work for applications needing the most precision and flexibility possible.

What’s more, because these machines are less complex, they are rather lighter on the budget and easy to maintain, hence suitable for small enterprises.

Semi-Automatic Tape Edge Machines

Semi-automatic tape edge machines are the midpoint between purely manual and absolutely automatic machines. While semi-automatic machines still require an operator, they come with more sophisticated features added to assist in handling mattresses of different sizes, for example, automatic height adjustment.

Semi-automatic machines have better productivity compared to purely manual ones since operators are relieved from much physical demand, hence allowing stitching that is smoother and more consistent.

Full-Auto Tape Edge Machines

Fully automatic tape edge machines are at the highest degree of automation, and therefore, suit large-scale mattress production facilities. These machines will automatically adjust to varying mattress sizes with very little input from an operator while keeping exact stitch alignment for high speeds.

Fully automated tape edge machines have the ability to provide the fastest throughput and are especially valuable when scaling operations for a manufacturer. The catch is that these new machines may be more expensive in terms of their initial purchase price but are capable of proving more economical in the longer term owing to the efficiency gains and savings in labor that they make possible.

Key Features to Look For in a Tape Edge Machine

Choosing the right tape edge machine requires understanding the critical features that can impact performance and ease of use. Here are some essential features to consider:

Adjustable Head and Table

This will be enabled by an adjustable head and table that will allow the machine to handle mattresses of different thicknesses and sizes. The adjustable aspect will be necessary for those manufacturers that offer a variety of product dimensions. A machine that has height adjustment capabilities will be easier to work with and give more consistent results across mattress types.

Speed Control Options

The question of speed is relevant to make sure that there is the right balance between production efficiency and stitching quality. Some materials need slower stitching to avoid damage or to make sure that they hold securely. Machines with variable speed options allow operators to optimize for both quality and throughput, adapting to different mattress types or specific stitching requirements.

Auto-Cutting Mechanism

An automatic cutting device trims excess tape on the end of every edge to streamline the finishing process. This feature reduces the need for manual trimming, saves time, and makes for a uniform edge finish, it minimizes material waste and gives way to cleaner lines of production.

Safety Features

Since the operators deal directly with the machines, safety features include emergency stop buttons, protective guards, and ergonomic design. This not only saves the operators but also avoids cases where accidents could have been prevented from bringing production to a standstill.

Benefits of Using Tape Edge Machinery

Tape edge machinery in the mattress manufacturing process provides a set of advantages that enhance the output regarding quantity and quality.

Enhanced Production Efficiency

The tape edge machines, particularly the automated ones, save a lot of time used by mattress manufacturers in finishing the edges. Actually, automated systems are able to undertake this operation at a much faster rate compared to manual sewing. In this way, manufacturers can increase their output without compromising on quality.

Consistent Quality and Durability

While manual stitching could have depended on the skillfulness and precision of the operator, tape edge machines ensure stitching that is uniform and accurate. Uniformity thus becomes a necessity in the production of quality mattresses that would last longer under normal usage and guarantee a good sleeping experience.

Labor Cost Reduction

However, automated tape edge machines minimize labor-intensive natures of the application and reduce skilled operators. It is a way to cut labor costs and reduce physical stress among employees, hence, it improves workplace safety and efficiency.

Maintenance and Troubleshooting Tips

Regular machinery maintenance on tape edge ensures performance at peak levels. These key practices will keep your machines running for long and reliably:

Routine Cleaning and Lubrication

Dust and other particles will settle on the machine. More so, build-up around moving parts will be great. Routine cleaning prevents build-up that may interfere with machine operation.

Also, lubrication of moving parts promotes smooth motion of the machine parts while minimizing wear and tear of components. It is important to note that cleaning and lubrication schedules are usually recommended by the manufacturer and should be followed as such.

Checking and Replacing Needles

Sometimes, the needles may grow dull or damaged over time, which leads to skipped stitches, or the seam might become poorly sewn. Still, frequent inspections and timely replacement of needles keep sewing quality high and the material intact. Using needles of good quality and suitable for the machine also prolongs the service life of the machine.

Inspecting Belts and Tension Settings

For smooth operation, tape edge machines operate on belts and tension settings. In that respect, most of these can be kept in good operating order by regular inspection of such parts to note any wear or poor adjustment that might cause disruptions. Then, adjusting the tension settings when needed will ensure that stitches are consistent and the machine can handle a wide range of material thicknesses.

Conclusion

Tape edge machinery is a cornerstone of efficient, high-quality mattress production. By understanding the various types, features, benefits, and maintenance needs of these machines, manufacturers can make informed choices to optimize their operations. For businesses looking to remain competitive, investing in reliable, up-to-date tape edge machinery is essential.

Связанные с ними товары