- Home » Customizable Features in Tape Edge Machines for Specific Mattress Types

In today’s competitive mattress manufacturing industry, tape edge machines play a critical role in defining the quality and durability of mattresses. The ability to customize these machines for different mattress types has revolutionized production processes, allowing manufacturers to offer a broad spectrum of mattress designs and features while ensuring efficient production.

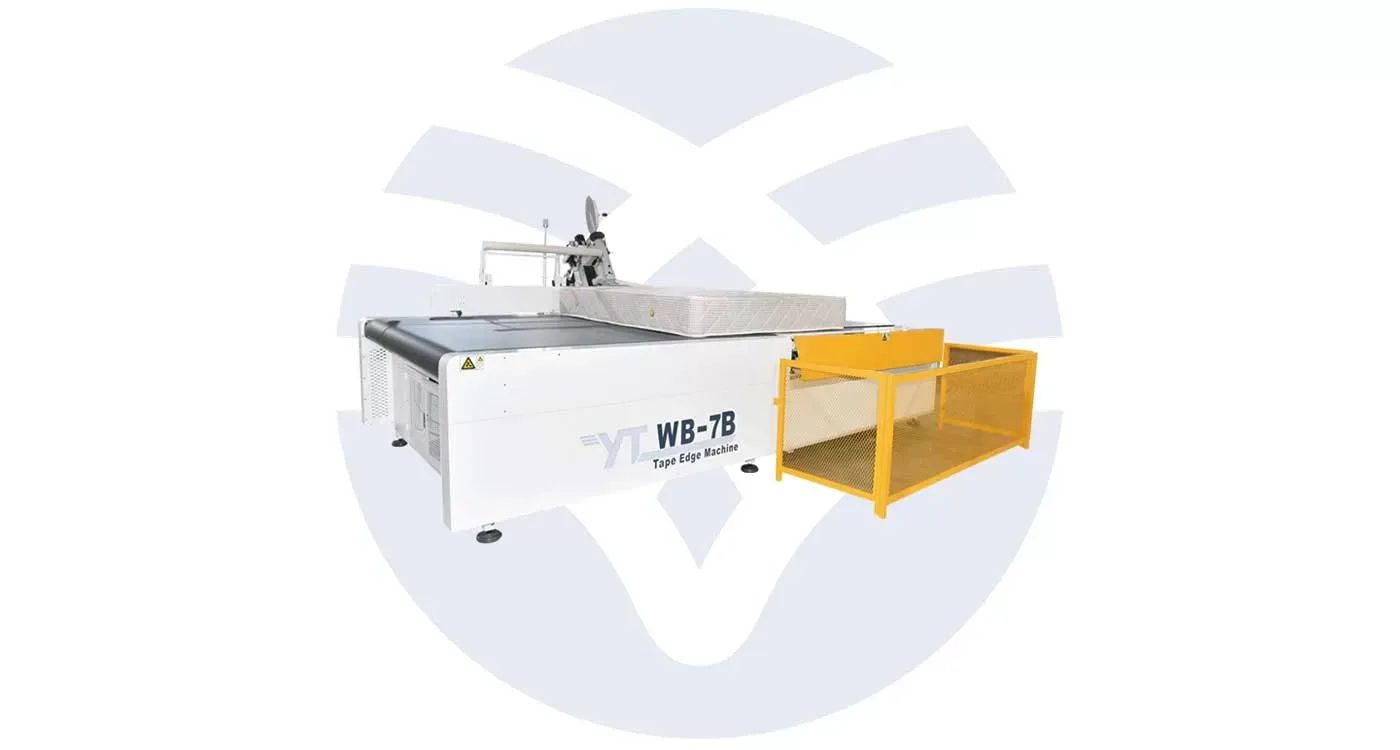

Understanding Tape Edge Machines in Mattress Manufacturing

Tape edge machines are special sewing machines that are specifically designed to seal the edges of a mattress with fabric tape. This is a very vital process, as it not only keeps the mattress layers together but gives a clean and finished look.

The functionality of tape edge machines goes beyond aesthetics to the effect on the durability, comfort, and overall performance of a mattress. In recent times, when the mattress industry is continuously adapting, there has grown an increasing demand for variability in features within these machines to meet the individual needs of different mattress types.

Basic Operation of Tape Edge Machines

In essence, a tape edge machine consists of a sewing head, a conveyor belt, and a guiding system through which the mattress travels, with its edges being stitched. The stitching head stitches tape onto the mattress edge, fully enclosing it.

Most machines offer either manual or automatic operation, depending on the level of automation desired on the production line. Today, however, mattress fabrics have become so varied and complex that additional capabilities have been required, some of which are more specific to mattress type.

Key Customizable Features of Tape Edge Machines

The ability for customization within tape edge machines is a response to demands to accommodate different mattress fabrics of varied thicknesses and designs. A few of the most important features a manufacturer can adjust or include to optimize production for certain types of mattresses are listed below.

Adjustable Sewing Head Height

One of the most important features for customization is that of sewing head height adjustment. Mattress thickness can be highly different between different types, some have thin foam mattresses, while others are very thick in either pillow-top or hybrid models. The height adjustment of the sewing head ensures that a machine is ready for this variation.

For example, spring mattresses tend to be thicker due to their coil system, while memory foam mattresses are much thinner. The adjustable sewing head lets you have precision stitching over a wide range of mattress profiles, thereby ensuring that the tape edge is securely fastened at any thickness of the mattress.

Speed and Automation Control

The level of automation and the speed of operation can be customized depending on the production scale and the specific mattress type being manufactured. A few contemporary tape edge machines boast programmable controls, where different stitching speeds for varied parts of a mattress can be set by operators. This is quite useful in dealing with mattresses that have complex designs, such as those with curved or contoured edges.

Automation control can also allow manufacturers to eliminate human error and subsequently provide consistent stitching quality. In the case of luxury mattress models that require detailed precision, semi-automated machines with manual adjustments can also be customized to offer more control over the finish of the final product.

Multiple Tape Width and Material Compatibility

There are many different types of mattresses that all require different types of edge tapes. These can differ in width, materials used, and so on, depending on the mattresses to be produced. High-end mattresses might use a decorative, wider tape, while budget models may be more suitable with a very basic narrow tape. Tape edge machines that can work with multiple widths of tape allow manufacturers easily to change from one style to another without too much downtime.

Besides the width, the material type of the tape is another prime consideration. The materials used in tapes vary from synthetic to natural fibers and each has its different tensions and needle configurations. Custom machines that can allow easy changeover between these without having to go through extensive recalibration give significant enhancements in efficiency, especially in production lines that cater to diverse mattress ranges.

Programmable Stitch Patterns

A very important feature for many tape edge machines is stitch pattern programmability. Mattresses designed either for orthopedic purposes or high-end luxury require more elaborate stitching to reinforce durability or add decorative flair.

Because the stitch patterns are programmable, manufacturers can adjust the appearance and strength according to the specific needs of a mattress. The inclusion of this feature makes for easier production of distinct product lines without having to use a completely different machine for each type of mattress.

Variable Pressure Control

Pressure control is another essential customizable feature, particularly for mattresses made with delicate or high-stretch materials like memory foam or latex. This is because excessive pressure applied during the stitching process of the tape edges leads to distortion or uneven sealing, which affects aesthetics and performance.

Many tape edge machines have variable pressure controls that enable the manufacturer to adjust the pressure according to the material used on the mattress. The softer the material, the less pressure you can apply to avoid dents in the mattress, whereas with high-pressure mattresses with a spring system, more pressure can be applied without causing damage.

Customization for Different Mattress Types

The diversity in mattress design has led to specific requirements for different types of mattresses. Customizable tape edge machines address these unique requirements, enabling manufacturers to optimize production based on the mattress type.

Spring Mattresses

The strong internal tension also demands the use of reinforced tape edge stitching in traditional spring mattresses. Thus, tape edge machines are normally required, with reinforced sewing heads and thicker tapes, so that the stitches can bear the internal tension of a mattress.

Machines with adjustable height features are important, considering the thickness of the mattresses, normally between 8 to 14 inches. Those with high-speed features will be advantageous, too, given the volume at which spring mattress production is made.

Memory Foam Mattresses

Memory foam mattresses are thinner and more flexible than their spring counterparts. That naturally means the tape edge machines apply less vigorous pressure to avoid distortion. In such cases, mattresses must have variable pressure controls, slower stitching speeds, and softer edge tape compatibility. Equally important is the fact that machines should be variable for thinner mattress profiles to allow for an efficient and even edge finish.

Hybrid Mattresses

Hybrid mattresses are a combination of spring and foam mattresses with added pillow tops or layers of latex. This causes yet another turn of events for the tape edge machines, which will need to adapt to several thicknesses, materials, and edge designs.

Machines that have a multi-option capability of adjustment of height, variable speed, and programmable stitching patterns turn out to be very useful in the production of hybrid mattresses. This ensures that the different layers are well-stitched without compromising on the aesthetic appeal of the mattress.

Specialty Mattresses

The luxury or specialty mattresses carry with them singular design features that require highly specified custom work for the tape edge machines. For example, an orthopedic mattress may employ specific stitching for support, while high-end models may implement aesthetic touches involving more complicated edge stitching.

This is usually done in the manufacturing process by ensuring stitch pattern versatility and tape material compatibility. Also, the machines with programmable settings enable the manufacturer to switch between models within the specialty category with ease and flexibility in production.

Conclusion

The evolution of tape edge machines into customizable tools has transformed mattress manufacturing, allowing producers to cater to a diverse range of mattress types efficiently. Whether it’s the adjustable sewing head height for different mattress thicknesses, programmable stitch patterns for added design flexibility, or variable pressure control for delicate materials, the features of modern tape edge machines can be tailored to specific production needs.

This level of customization not only increases productivity but also enhances the quality and durability of mattresses, helping manufacturers stay competitive in an increasingly diverse market. By embracing these customizable features, mattress manufacturers can meet the growing demands of consumers seeking personalized comfort and design in their sleeping products.

Связанные с ними товары