- Home » Cost-Benefit Analysis of Mattress Tape Edge Machines

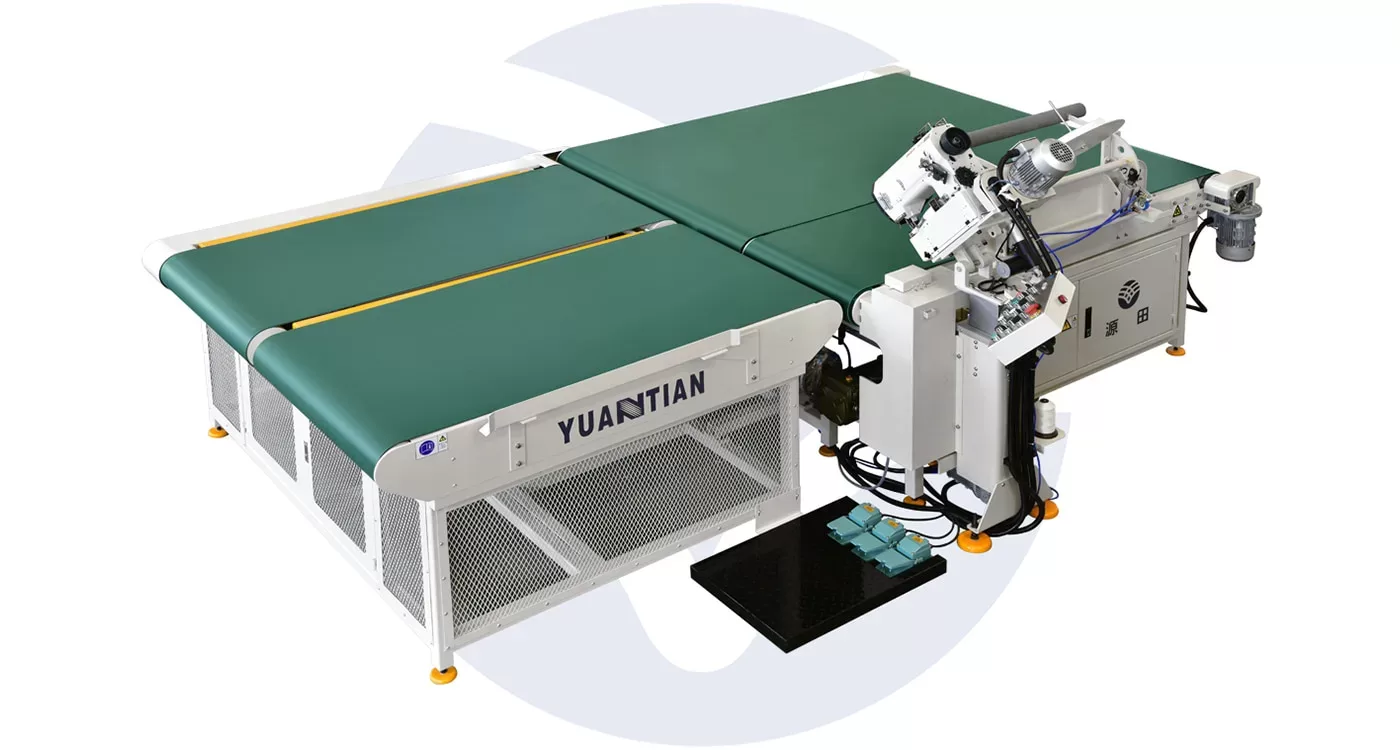

Mattress tape edge machines play a vital role in the final assembly phase of a mattress. These machines securely attach the edges of the mattress while providing structural integrity and a finished finish to the mattress.

This article discusses investing in a mattress tape edge machine and provides an in-depth cost-benefit analysis of the investment in terms of initial cost, operating expenses, productivity gains, quality improvements, and long-term benefits.

Initial Costs

Purchase Price

Mattress tape edge machines are available at different prices, depending on the model available, features, and of course, the brand. Those with computerized controls, automatic settings, and other frills added to them can be very expensive due to the added features.

While the initial investment may seem substantial, the advanced capabilities of these machines can offer long-term benefits that outweigh the upfront costs.

Installation and Setup

In addition to the purchase price, there are costs associated with installation and setup. The expert installation makes sure that the installation is secured and properly adjusted so that the machine operates faultlessly from day one within the production process and minimizes potential problems and downtime. These costs include labor, calibration, and initial training for operators.

Training

Training costs represent a crucial part of the set-up investment. The operators have to be equipped to run the machine effectively enough to exploit the full potential of the machine at the proper safety standards. Usually, full-fledged training schemes from the manufacturer allow staff members to run the machine properly and service it for basic maintenance work.

Operational Expenses

Maintenance and Repairs

Optimal tape edge machines should be maintained regularly so as to function properly. Regular inspection should be maintained, the worn machine parts should be replaced, and the machine should be scheduled for service.

All this will incur a cost during the process, and the cost involved is maintenance cost. Preventive maintenance will minimize the requirement for expensive repair work and also raise the life of the machine.

Energy Consumption

Energy consumption features one of the highest operational costs. Advanced tape edge machines, therefore, are designed to be energy-saving and reduce the total energy charges. Comparing energy consumption in different models can allow manufacturers to choose the one that strikes a balance between energy efficiency and performance.

Consumables

Consumables like thread, needles, and lubrication are some of the ongoing costs of operating tape edge machines. These consumables are capable of affecting both the cost and the performance of the machine. It is sometimes worth investing in more expensive consumables to reduce downtime and improve the quality of the finished product.

Productivity Gains

Speed and Efficiency

Modern tape edge machines are designed to handle high speeds, which also means a very significant rate of increasing productivity. Such machines can finish edge stitching much faster than manual or older models, thus enabling a manufacturer to make more mattresses within a given time frame. Higher speeds and efficiency mean higher outputs at lower labor costs.

Consistency and Precision

It is this precision of the machine that stitches that brings down the scope of defects in stitching and rework. Consistency in stitching is the key to not only achieving an aesthetically appealing look for the mattress but also, at the same time, enhancing durability. The result is that returns are saved, and customers are satisfied.

Reduced Downtime

Most advanced tape edge machinery comes with automation that not only reduces the manual intervention required but often includes an automated thread cutting and tension adjustment feature. Further, it has a built-in diagnostic system to call out possible problems to the operator so that action can be taken before there is a real consequence of disruption.

Quality Improvements

Enhanced Durability

The tape edge machines make a mattress edge have a very strong and secure finish that greatly improves durability. This secure stitching at the edges avoids fraying and thus, with a full mattress intact, is important from the viewpoint of the customer for satisfactory and long-term use. It reduces repairing and replacing costs in the long run.

Aesthetic Appeal

As a tape edge machine gives better edging, it tends to make a mattress look better and smoother at its edges, thereby increasing aesthetic appeal and yielding added value to the customers.

The professional and clean finish obtained from a tape edge machine adds value to the mattress in terms of appearance. Neat stitching adds value to the product in the view of the customer, therefore making it look more presentable for purchasing. This might translate into a better finish to justify a higher price and be competitive in the market.

Compliance with Standards

There are strict mattress manufacturing standards in many markets. Tape edge machines help in assuring that the standard is met with consistent, high-quality stitching. Eliminating legal hurdles through compliance with industry standards sometimes builds a brand reputation that customers trust, and that is why many customers prefer standardized products.

Long-Term Benefits

Return on Investment (ROI)

A quality tape edge machine is surely going to pay for itself several times over a short period. The initial costs are more than offset by increases in productivity, reductions in operational expenditure, and gains in product quality.

When calculating all these benefits, consider the increased production capacity, the savings that occur with reduced defects and downtime, and the new capabilities for commanding premium prices for better products.

Competitive Advantage

What is more, tape edge machines of more advanced designs by the manufacturers add to the provision of very high quality, yet at very competitive prices, products. This has helped to gain greater market share and set customer royalty. The scalability strength is further enhanced by the capability of adapting in a short time to changes in market trends and consumers’ demands.

Scalability

An increased demand for mattresses makes the ability for efficient scaling of the production facilities. With tape edge machines, the manufacturer can add production at low labor-cost escalation. This enables growth in demand for the increased number of mattresses without loss in quality and efficiency.

Conclusion

The cost-benefit analysis of mattress tape edge machines reveals that the initial investment and operational expenses are outweighed by significant gains in productivity, quality, and long-term profitability. Advanced tape edge machines offer speed, precision, and durability, contributing to enhanced product quality and customer satisfaction.

As the mattress industry continues to evolve, investing in modern tape edge machines can provide manufacturers with a competitive edge, scalability, and a robust return on investment.

Связанные с ними товары