- Home » Comparing Manual and Automatic Mattress Tape Edge Machines

The mattress industry has seen significant advancements over the years, particularly in the manufacturing processes that ensure the quality and durability of the products. One critical aspect of mattress production is the tape edging process, which involves stitching the mattress edges to secure the inner materials and provide a neat finish.

This process can be manual or automatic, and each category has its advantages and challenges. This article examines the differences between the two, especially with respect to factors like efficiency, costs, precision, and compatibility with different production scales.

Understanding Manual Mattress Tape Edge Machines

Manual tape edge machines have a high degree of human interference with operation. The operator passes the mattress through the machine to ensure that the tape is straight and sewn evenly. The major kinds of machinery in this category will contain a sewing head that has been mounted on a track system. The operator can move the sewing head in and out of the mattress perimeter.

Advantages

Cost-Effectiveness: One of the primary benefits of manual tape edge machines is their lower initial cost compared to automatic machines. This makes them an attractive option for small to medium-sized mattress manufacturers or those just starting in the business.

Flexibility: Flexibility is a major factor that would lead to the preference of manual machines over their automatic counterparts when buying the tape edge machines. This is most ideal for those entities that are either small or medium-sized mattress manufacturing companies, or those that are starting up in the business.

Manual machines are more flexible in handling mattresses of different types and sizes. Since it is operated manually, one can make adjustments for individual mattress needs and may thus be able to customize it with features that may not be compatible with a mattress using automatic machines.

Challenges

Labor-Intensive: These manual machines are operated with high labor intensity and depend on immediate skilled operators who can ensure the delivered quality level of the final stitching. Human dependence results in inherent inconsistencies with the final product, increasing labor costs over time.

Production Speed: Manual machines take more time as compared to automatic machines. The reason is that manual machines depend on human operation. Therefore, the speed at which one produces is the effectiveness of operation and human fitness, thus a human bottleneck in the high volumes manufacturing environment.

Exploring Automatic Mattress Tape Edge Machines

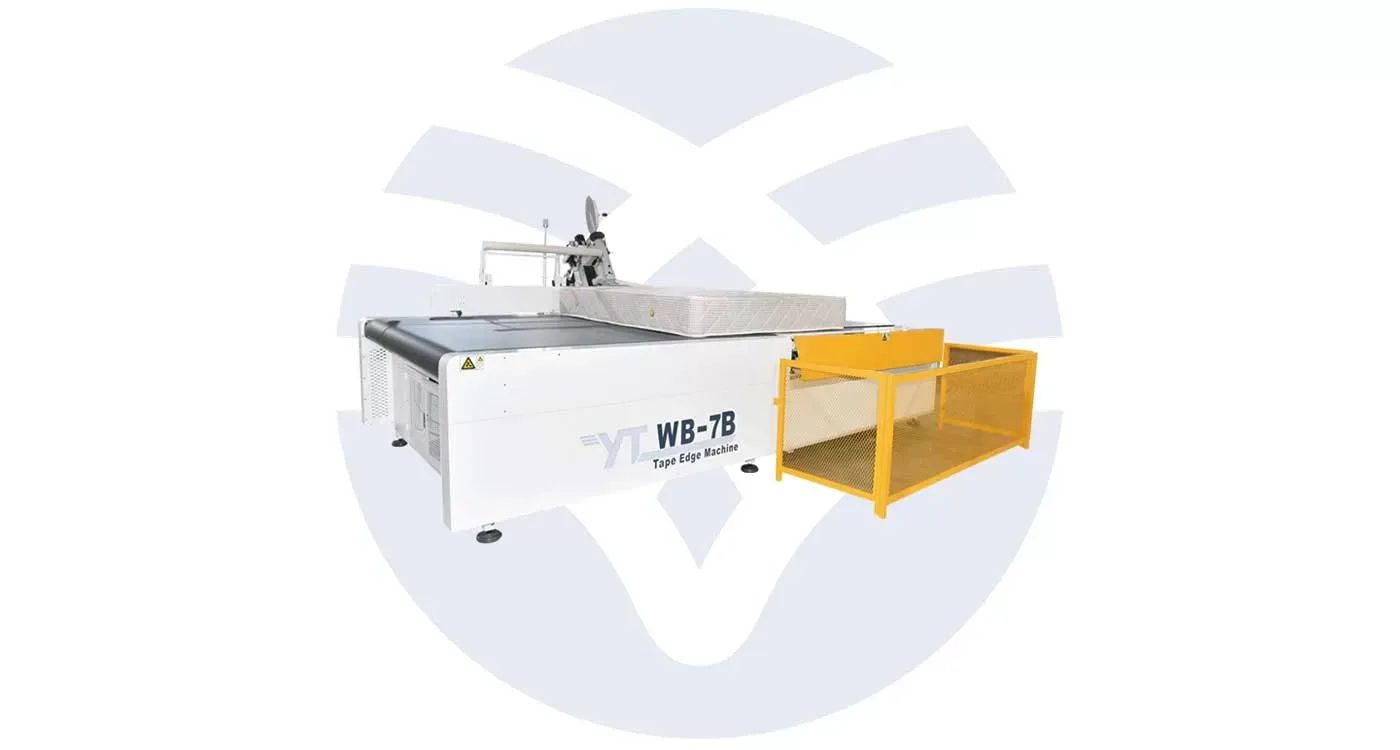

Automatic mattress tape edge machines are created to do away with human input, they are designed with state-of-the-art robotics and control systems that take care of the stitching process. These machines can be set up to stitch any mattress size and type and, in most instances, come with a program that allows it to be set in line with a specific product.

Advantages

High Efficiency: One of the most significant advantages of automatic tape edge machines is their high efficiency. Non-stopping ability with a few labor results in boosting the production speed and output many times over, providing it as applicable to the very high-volume producers who can churn out bulk orders of mattresses.

Consistent Quality: Precision and uniformity are done using the aid of automatic machines that are quite not easily possible with the human option. Each stitch is correctly positioned using the automated systems in each mattress, hence giving equal and professional finishes for all mattresses. Such consistency is a dire need for the maintenance of proper quality to regard products and customer satisfaction.

Challenges

High Initial Cost: The main disadvantage of the automatic tape edge machines is their relatively high cost at the time of purchase. Used in the construction of the machines are the high-order technology and equally the high quality types of equipment, making them relatively high in price. Nevertheless, this can be compensated for over the long period by increasing productivity and lowering labor costs.

Maintenance and Technical Expertise: Automatic machines require regular maintenance and occasional technical support to ensure they operate smoothly. This means manufacturers need to invest in training for their staff or hire technicians who can handle these machines, which can add to the operational costs.

Comparing the Two: Key Considerations

Cost and Return on Investment

Cost is arguably the most important variable when considering a manual versus automatic tape edge machine purchase. Although manual tape edge machines have a lower capital investment, the long-term labor costs and comparatively slow production time might make this a costly option. Automatic machines require a high capital investment in the machines themselves but can result in greatly reduced labor costs and greater efficiencies in volume production.

Production Volume and Speed

For manufacturers with high production volumes, automatic machines are generally more suitable. They are well-equipped to operate indefinitely and carry out operations without deviating from the standards. On this note, the manual ones come in handy for small-time manufacturers or orders of a custom or low production volume, whereby the flexibility requirement is realized, and the initial cost is lower.

Quality and Precision

The workmanship of automatic machines is generally more precise than that of manual machines. The automated control systems are likely to make sure that each mattress is finished with the same high quality, and this is the key to building a reputation for quality. Manual machinery, even with the ability to produce high quality, is still based upon the skill and consistency of the operator, which can vary greatly.

Flexibility and Customization

Manual machines are very flexible in customization, it is possible to make various settings “on the fly.” It is very important for a manufacturer who specializes in creating individually designed mattresses or one who works with a wide variety of models. On some level, automatic machines are just as programmed but need extensive pre-setting, not making different variations on the spot.

Conclusion

The choice of either manual or automatic tape edge mattress machines depends on budget, production volumes, quality needs, and flexibility. Manual machines come with a low initial cost and can have many cases of adjustment, hence most specifically for manufacturers making low to medium volumes or those into the customization of mattresses upon demand. Automatic machines ensure a high level of productivity while maintaining a uniform level of quality and are therefore most specific for manufacturers with very high levels of manufacturing.

Ultimately, the decision will depend on an understanding of the specific needs and goals of your manufacturing business. If manufacturers have careful consideration for the advantages they may accrue from the different types of machines and it relates to differences and disadvantages connected with each, then an informed choice will be made in the best interest of the business intentions and set objectives.

Связанные с ними товары