- Home » Choosing the Best Mattress Compression Machine for Shipping Efficiency

Shipping efficiency is a critical factor in the mattress manufacturing industry, especially with the rise of e-commerce and direct-to-consumer sales models. Compressing mattresses before shipping is a common practice that reduces shipping costs and environmental impact by minimizing packaging size.

However, choosing the best mattress compression machine is crucial to maintaining product quality while maximizing shipping efficiency. This article explores the key factors to consider when selecting a mattress compression machine, ensuring that your investment aligns with your operational goals and enhances overall shipping efficiency.

Understanding Mattress Compression Machines

Before looking at what one should consider when selecting one, let’s understand what mattress compression machines are and how they interact in the shipping process.

What is a Mattress Compression Machine?

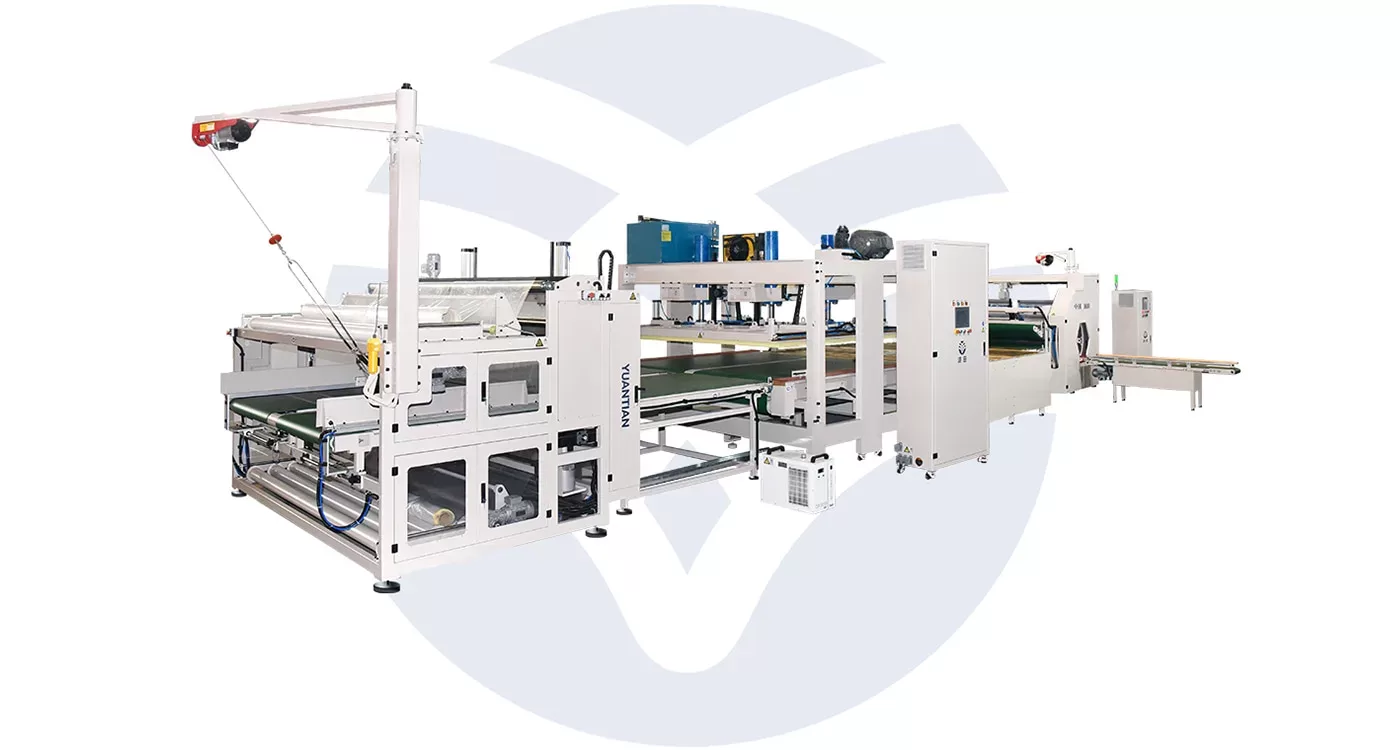

A mattress compression machine is a special kind of equipment that compresses and then rolls or folds mattresses into a much smaller form. This greatly reduces the overall size of the mattress and facilitates much easier and more cost-effective shipping.

The machine applies pressure uniformly across the mattress, ensuring that it retains its structural integrity and comfort when it is unpacked by the customer.

The Importance of Compression in Mattress Shipping

Compression plays a vital role in optimizing shipping efficiency. Smaller packages take up less space in a shipping container, thus allowing for more units to be shipped together in one go, which reduces the shipping cost per unit.

In addition, smaller package sizes reduce packaging material used and fewer shipments, which, in turn, reduces carbon emissions from delivery. Because these mattresses are easily compressible, handling and transportation become easier.

Key Features to Consider in a Mattress Compression Machine

In selecting a mattress compression machine, several key features must be evaluated so that the machine will be capable of meeting operational needs and shipping efficiency goals.

Compression Force and Capabilities

Performance is greatly determined by its compression force and capability. It should be able to compress with forces that can bear the types of mattresses you make. Compressive forces that may be used on foam mattresses may differ from those used for innerspring or hybrid mattresses.

Some machines have different options of compression settings, such an option helps a manufacturer perfect the compression of a particular mattress type and size to get the best outcome without damaging the product.

Speed and Throughput

The operational speed of the mattress compression machine has direct implications for production efficiency and shipping timelines. The faster a machine works, the more mattresses can be compressed in a very short time, raising throughput. This is considered important to a high-volume manufacturer who has to fulfill tight shipping deadlines.

Look for machines that can sustain a continuous operation and allow for the least amount of downtime. Features such as the automation of material feeding and cooling help in sustaining high levels of productivity.

Automation and Integration

Large-scale automation capability is the greatest advantage in modern manufacturing, and mattress compression machines blended into automated production lines ensure increased efficiency. Machines can be fitted with automated controls and programmable settings so that any level of compression needed comes out perfectly the same, with very little human input required or risk associated with human error.

Also, consider ease of integration with your current production line. Such machines that can be easily connected to other machinery, such as packaging machines and conveyors, enable a more fluent production process by reducing handling time.

Durability and Maintenance

Comfort gained by mattress compression does indeed depend a lot on the durability or ease of maintenance the machine can provide. You should go for those machines manufactured from high-quality material that stands up to the demand for continuous operation. Features to look out for include reinforced frames and wear-resistant components.

The ones that are easy to access for critical components and whose maintenance protocols are more straightforward will obviously suffer from less lost time and an extended life. Some of the high-end models even offer predictive maintenance features wherein early warnings can be issued to operators for any potential issues, thereby preventing major problems from arising.

Evaluating the Impact on Product Quality

While effectiveness in shipping is important, it must not come at the cost of the quality of the product in question. The comfort, durability, and appeal of the mattress must not be affected by the compression procedure.

Quality Retention Post-Compression

A high-quality mattress compression machine should give confidence that mattresses retain their characteristics even after passing through compressions and decompression. The machine will apply uniform pressure on the entire surface of the mattress without harming internal parts such as springs or foam layers.

Those machines with soft-touch rollers or cushioned surfaces further minimize any chance of damage to the sensitive material during the compression process.

Testing and Quality Assurance

This should be a consideration if the machine has inbuilt features that offer testing or quality assurance. Sensors or systems to check the integrity of the mattress after compression may be used so that only products meeting the set standards go to packaging.

Machines with better and more evolved control systems provide consistent compression results, reducing variability that could affect product quality.

Customization and Future-Proofing

As market demands evolve, the ability to customize and upgrade your compression machine can provide a competitive edge.

Customization Options

A few mattress compression machines have various features for customization based on the specific operational needs one may have.

The modular design of some machines allows the addition of features whenever desired, hence offering flexibility in production. The different settings that are available for customization allow manufacturers to alter the compression process according to different models of mattresses or special packaging requirements.

Future-Proof Your Investment

Investing in a machine that can adapt to future needs is crucial for long-term success. Choose a machine that offers easy upgrades to accommodate new mattress designs or changes in packaging standards. Machines that can scale with your business growth ensure that your investment remains valuable as production demands increase.

Conclusion

Choosing the best mattress compression machine involves a careful evaluation of various factors, from the machine’s technical capabilities to the impact on product quality. By selecting a machine that aligns with your operational goals and offers long-term benefits such as reduced shipping costs, enhanced product quality, and adaptability to future needs, you can significantly enhance shipping efficiency and overall business profitability.

Связанные с ними товары