- Home » Boost Your Mattress Production with the Best Mattress Border Machines

Over the past years, the industry of mattress manufacturing has been developed and accompanied by the emergence of several new technologies in the production lines that increased the quality of their products. The border mattress machine is just one of the innovations developed in this field, which revolutionized the production of mattress borders.

In this article, we will discuss several issues involving mattress border machines, including their features, benefits, and their impact on the mattress industry.

Importance in Mattress Manufacturing

Mattress border machines in mattress manufacturing are important, for they are designed with the ability to stitch and finish borders of mattresses in order to provide durability and aesthetic appeal. Precision and consistency in the result that these machines give make them very important in contemporary mattress manufacturing.

How Mattress Border Machines Work

Key Components

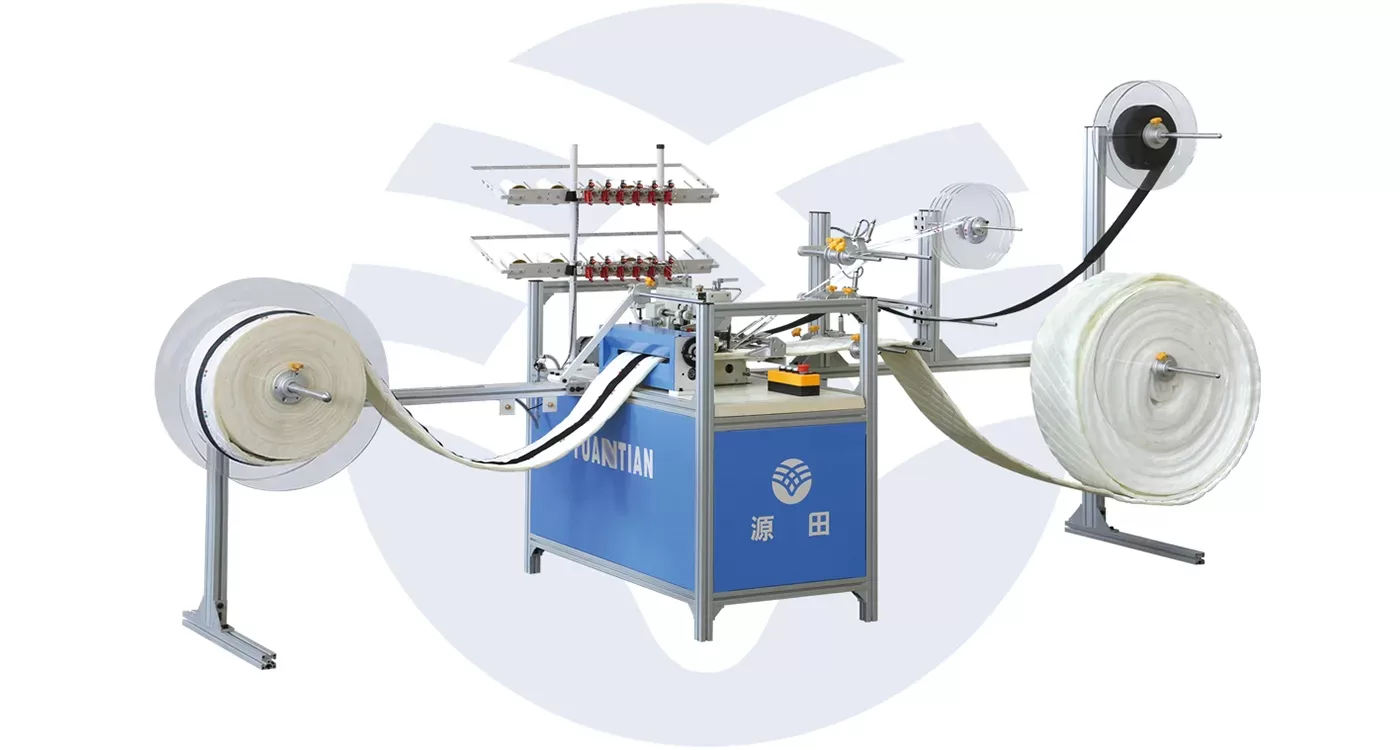

The coat border machine shall have some integral parts, such as the frame, sewing head, fabric feeding system, and control panel. All of these components play a crucial role in ensuring the smooth running and efficiency of the machine.

Functionality

These machines work by passing the border fabric through the sewing head, which sews the same based on pre-set patterns. The control panel permits operators to adjust facilities such as the type of stitch, speed, and tension that help to produce a finished product per specifications.

Types of Mattress Border Machines

The choice of the type of mattress border machine should be based on the needs in terms of production. Some machines offer a unique combination of capability, efficiency, and level of automation that provides manufacturers with choices to select the best equipment for specific requirements in their production. The discussion below looks at the main types of mattress border machines available in the market and their respective features.

Single-Needle Machines

The single-needle mattress border machine is the most simple type of border machine available. They are normally used for small production volumes or in small shops. These machines are easy to operate as well as service, thus they are economical for those manufacturers whose production volume is low.

Single-needle machines provide basic stitching functions—this is the simple, consistent stitching along the border of a mattress. Though they don’t have major features like the more advanced models, they are also stable and powerful for simple stitching. Thus, this also becomes an entry point for most startups or small mattress manufacturers just getting along with their automation initiative.

Double Needle Machines

Double-needle mattress border machines are more advanced than single-needle ones and designed to satisfy medium-to-large-scale production needs. This would be the style of machine any manufacturer looking to achieve higher daily or hourly volumes would want, without risking lower quality stitching or tensile strength.

The double-needle machines can sew more strongly and thereby make stronger stitches. Because they are fitted with two needles, it is possible for them to make stronger seams—important for high-quality mattresses that need extra durability. That way, mattress borders are more resistant to wear and tear, providing better long-term performance.

Multi-Needle Machines

Multi-needle mattress border machines are designed to run in high-volume manufacturing environments. Thus, their design and features make them quite appropriate for large production lines. Hence, they can fit into large mattress manufacturers seeking to produce high volumes of mattresses quickly.

One of the great features of multi-needle machines concerns running several borders at once. This greatly increases production speed and efficiency, as all needles work independently on various parts of the mattress border simultaneously. This not only reduces the production time by a number of stitches but also ensures uniform stitching on all borders of the mattress.

Computerized Border Machines

The most superior in modern manufacturing technology has to be the computerized mattress border machines. These machines contain advanced and complicated computerized systems that automate a lot of features of stitching and, therefore, give very precise control over stitching patterns and parameters.

These machines have been highly automated due to their computerization, bringing down the element of manual intervention. This makes stitching more consistent and accurate since a computerized system can be pre-programmed to follow a variety of patterns with a very high level of precision.

Most such machines are also equipped with other user-friendly features, such as touch screens, programmable settings, and real-time monitoring. This, in turn, enhances their overall productivity and effectiveness.

Advanced technology integrated into computerized border machines helps give greater versatility in stitching patterns. Hence, it becomes easy to change over to different designs and styles to suit customers changing varied preferences and various market demands. This flexibility is something very vital in the competitive market where differentiation of products brings success.

Key Features of Modern Mattress Border Machines

Automated Controls

State-of-the-art machines are designed with automated controls, which are easy to operate and set for desired outputs. This means a relatively easy process of setting variables such as stitch length, pattern, and speed.

Customization Options

A significant number of mattress border machines offer customization options. This provides manufacturers with greater flexibility in creating divergent designs and patterns. Flexibility is exceedingly important for differentiation in a competitive market.

Benefits of Using Mattress Border Machines

Mattress border machines are becoming an integral part of modern mattress manufacturing due to their number of advantages. These machines have a number of advantages over the manual processes of sewing, which have resulted in increased productivity, quality consistency, and overall improvement in manufacturing efficiency.

Increased Efficiency

One of the most striking advantages connected with mattress border machines is their capacity to work continuously. In contrast to manual operations involving frequent breaks and changes in shifts, the machines can be run continuously to maximize production time. This capability of keeping the machines at full tilt is especially useful to large manufacturers hoping to fill demands that are high and schedules tight.

Mattress border machines save a great deal of production time. The automated machines can do stitching jobs at speeds way much faster than any human worker by way of the speeds and precision they attain. For instance, a task that could take a manual operator several minutes is done by a machine in less than a minute.

Consistent Quality

It is very important to have consistency in product quality in the mattress industry. The most minor flaws may potentially alter product performance and durability. Mattress border machines achieve the highest level of consistency in stitching quality.

The precision and accuracy of the mattress border machine reduce to a large extent the possibility of defects. Automated machines follow the exact patterns and parameters, thus avoiding inconsistencies that can be caused by manual sewing. This will ensure that every border for a mattress is sewn right with no skipped stitches and irregular patterns.

Mattress border machines directly influence the durability of the end product because they provide quality consistently. Mattresses with well-stitched borders show fewer tendencies to unravel at the seams or wear unevenly. Enhanced durability further elongates the life of the mattress and gives more value to the customers.

Cost Savings

Though the initial investment in mattress border machines is high, there are certain economies in labor costs in the long run. These automatic machines require a lesser number of operators to control the sewing process; hence, the manufacturer can either reduce the workforce or deploy labor resources to other more essential production functions.

Mattress border machines reduce material wastage due to their construction, which provides maximum optimization of material usage and reduces wastage to the least minimal dimension.

Versatility and Flexibility

Mattress border machines are very versatile and can be set up to make a wide range of stitching patterns or designs. A factor like this is key in a competitive market whereby manufacturers have to offer varied product lines in order to satisfy the different tastes of customers. Fast and easy changes to stitching patterns offer the manufacturer an excellent opportunity to react more quickly and effectively to changes in market demand.

Innovations in Mattress Border Machines

Latest Technologies

Mattress border machine innovations put together the integration of AI and IoT technologies, making the machines capable of online monitoring, along with predictive maintenance, to further enhance the efficiencies of the machines.

Future Trends

The mattress border machine marches into the future, as there are continuous studies going on with regard to the development of more energy-efficient and ecologically fit machines.

Impact on the Mattress Manufacturing Industry

Efficiency in Production

Mattress border machines have made a huge difference in production efficiency. Much time and labor taken by border stitching is significantly reduced, opening up the opportunity to entertain higher demand.

Cost Reduction

Manufacturers were losing money on labor and wasting materials before the process was automated; with the invention of the border stitching machines, these problems went out of the window.

Conclusion

The machines for mattress borders have changed the very concept of mattress making with regard to efficiency, uniformity in quality, and cost reduction. Further advancing in technology, these machines will remain integral parts of every production process, further innovating and fueling growth in the industry.

Связанные с ними товары