- Home » Automated Packaging Machines: Streamlining the Final Step in Mattress Production

Automated packaging machines have revolutionized various manufacturing industries, and the mattress industry is no exception. As mattress manufacturers strive to meet growing demand while maintaining product quality and reducing operational costs, automated packaging solutions have emerged as a critical tool in optimizing the final stages of production. These machines not only enhance productivity but also ensure consistency and precision in packaging, which is crucial for both shipping and customer satisfaction.

In this article, we will explore the role of automated packaging machines in the mattress production process, their benefits, and the technology that drives their efficiency.

The Role of Automated Packaging in Mattress Production

From Manual to Automated Packaging

Traditionally, the process of packing mattresses has been labor-intensive and very time-consuming. Workers will wrap each mattress and secure it manually. Due to this being a manual job, inconsistencies resulted in irregular quality packaging that raised the potential for damage during transport. Moreover, it involves a high degree of labor costs in manual packaging and increases the risk of workplace injuries with the associated heavy physical demands of this job.

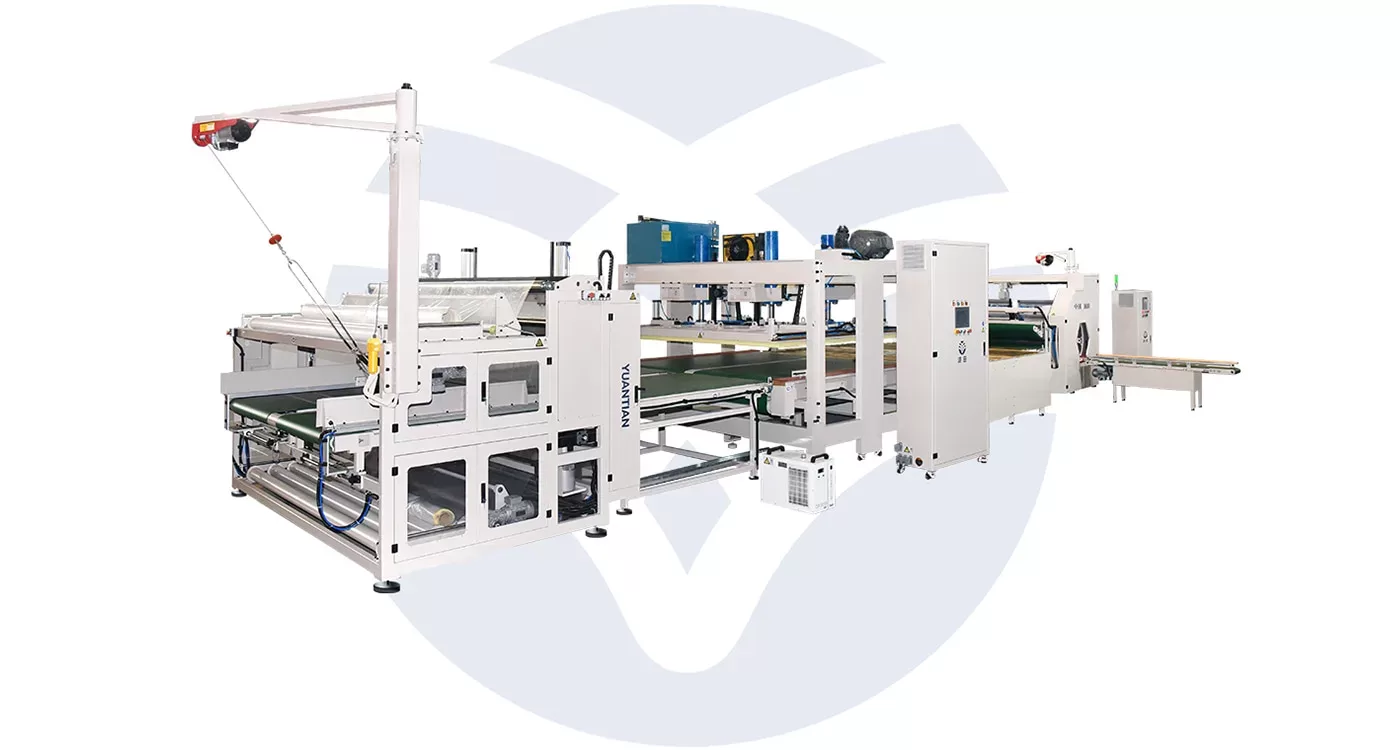

The introduction of automated packaging machines in this field saw much of the human effort replaced by a mechanized system that could undertake the same duties more effectively with a touch of precision and speed. Wrapping, sealing, compressions, and boxing of mattresses are functions conducted by machines to reduce human interference and errors, and to increase efficiency in production.

Key Functions of Automated Packaging Machines in Mattress Production

Automatic packaging machines are designed for a number of important functions in mattress production. These include:

- Wrapping: The machine wraps the mattress in a protective film, typically polyethylene, to safeguard it against dust, moisture, and potential damage during transport.

- Compression: To save space during shipping and storage, the machine compresses the mattress, significantly reducing its size. This is especially important for companies that ship mattresses in compact boxes directly to customers.

- Sealing: The machine seals the packaging to ensure that the mattress remains securely wrapped. This is crucial for maintaining product integrity and preventing exposure to external elements.

- Boxing: In some cases, the machine places the compressed and sealed mattress into a shipping box. This is common for brands that offer mattresses in a box, a popular option for e-commerce companies.

Benefits of Automated Packaging Machines

Enhanced Efficiency and Productivity

The biggest plus associated with automated packaging machines is the fact that they increase productivity. Manual labor can hardly keep up with such machines, because they can handle hundreds of mattresses per hour. Consequently, they would put manufacturers in a better position to answer rising demands. This increase in efficiency translates into faster order fulfillment, reduced lead times, and higher throughput.

Automation allows repetitive tasks to be handled and frees a manufacturer’s workforce to higher-value activities such as quality control or research and development. This optimizes labor use and reduces dependence on manpower, which can be slower and more prone to errors.

Improved Consistency and Packaging Quality

Automated packaging machines bring a lot of consistency in the way mattresses are packaged. Each mattress would be wrapped, compressed, sealed, and boxed the same. Due to this, the quality of packaging produced would always be consistent. This helps protect mattresses during their transit and storage while reducing the possibility of damage.

In addition, automatic machines are programmed to follow strict specifications. Therefore, each package produced will meet the established standards. This will reduce over-packing or under-packing, which may result in too much material being used or too little protection.

Cost Reduction

Although the initial investment in automatic packaging machines can be great, the amount saved through this is pretty significant in the long run. Automation minimizes the use of human input, which accounts for the largest share of the costs incurred during any operation. Secondly, these machines waste minimal material by using only the exact amount required as packaging material, bringing down overall expenses.

Automation also helps reduce shipping costs because mattresses are compressed into smaller, more compact sizes, allowing manufacturers to ship more units at a time, thereby reducing shipping costs. E-commerce companies also benefit because smaller packages can now be shipped at a lower price.

Enhanced Safety for Workers

Packing mattresses by hand implies heavy lifting and repetitive actions. All these threaten workers with traumas of strains and sprains, back injuries, and even more serious conditions. Automation in mattress packaging machines mitigates these risks since such machines will relieve the employees of the physically demanding part of the job.

These machines provide a much safer working environment and a lower incidence of workplace injuries, as the need for human intervention is drastically reduced. This is to the advantage of the employees, as well as another cost-saving opportunity from having fewer workers’ compensation claims and lost productivity from absence due to an injury.

Space-Saving Solutions for Shipping and Storage

Compression technology also happens to be one of the sought-after features of automated packaging machines when it comes to mattress production. Compressing mattresses allows for saving space, both in storage and at the time of shipping. A compressed mattress occupies much less room space, therefore, more units can be stored by the manufacturer in their very own warehouses, and greater numbers of items can be shipped in one load.

This facility for saving space is much in demand by mattress companies that send the products directly to consumers. The ability to place a full-size mattress in a box of compact dimensions makes home delivery much easier to contemplate and afford, hence the growing popularity of “mattress-in-a-box” solutions.

Types of Automated Packaging Machines for Mattresses

Mattress Roll-Pack Machines

Among the automatic packaging machines, one popular model used for the mattress industry is the roll-pack machine. These compress mattresses and then tightly roll them into cylindrical shapes which are further enveloped and sealed with plastic. Companies that ship mattresses in a box most often apply this type of machine, which allows big mattresses to be fitted into small and easy-to-handle packages.

All the roll-pack machines include high-pressure rollers that seal the mattress and keep it safely compressed through shipment or storage until unpacking. They are viable for a wide range of sizes and types, including memory foam, latex, and hybrid models.

Vacuum-Pack Machines

Another popular option in mattress packaging is the employment of vacuum-pack machines. Using vacuum technology, these machines suck air out of the packaging, compressing the mattress to a fraction of its original size. Once all the air has been sucked out of the mattress, the machine then seals the mattress in airtight packaging to keep it compact until it is unpacked by the consumer.

The machines are ideal for those business entities that want to save on space during shipment and storage since they compress the mattress to smoothen it out, usually, this is in addition to roll-packing so as to achieve maximum compression.

Heat-Seal Machines

Heat-seal machines are designed to wrap mattresses in protective plastic film and use heat to seal the edges. These machines provide a strong and durable seal to avoid exposure to dust, dirt, or moisture. This is a crucial stage that shows how a mattress maintains its prima condition right from the production floor to the customer’s home.

Seal machines are very often set up in conjunction with other types of packaging machines, such as a roll-pack or vacuum-pack system to provide a fully automated packaging line.

Conclusion

Automated packaging machines have transformed the mattress production industry, offering a host of benefits including increased productivity, enhanced packaging quality, cost savings, and improved worker safety. By streamlining the final step in mattress production, these machines allow manufacturers to meet growing demand efficiently while ensuring that their products reach customers in perfect condition.

As technology continues to evolve, automated packaging machines will become even more advanced, incorporating AI, IoT, and smart sensors to further enhance their capabilities. For mattress manufacturers looking to stay competitive in a rapidly changing market, investing in automated packaging technology is a strategic move that offers long-term rewards.

Связанные с ними товары