- Home » A Comprehensive Guide to Mattress Tape Edge Machines

Mattress tape edge machines play a crucial role in the manufacturing of mattresses, ensuring that the edges are securely bound and aesthetically pleasing. These machines are indispensable for producing high-quality, durable mattresses that meet the demands of today’s discerning consumers. This comprehensive guide explores the various aspects of mattress tape edge machines, including their functionality, types, key features, benefits, and maintenance tips.

Understanding Mattress Tape Edge Machines

What is a Mattress Tape Edge Machine?

A mattress tape edge machine is a special machine used for the finishing line, it is for stitching the sides of a mattress. This is to contain the cover and the inner parts giving a clean look when the process is done. Tape bound is used on all four vertical sides, this is why it’s called a tape edge machine.

How Does it Work?

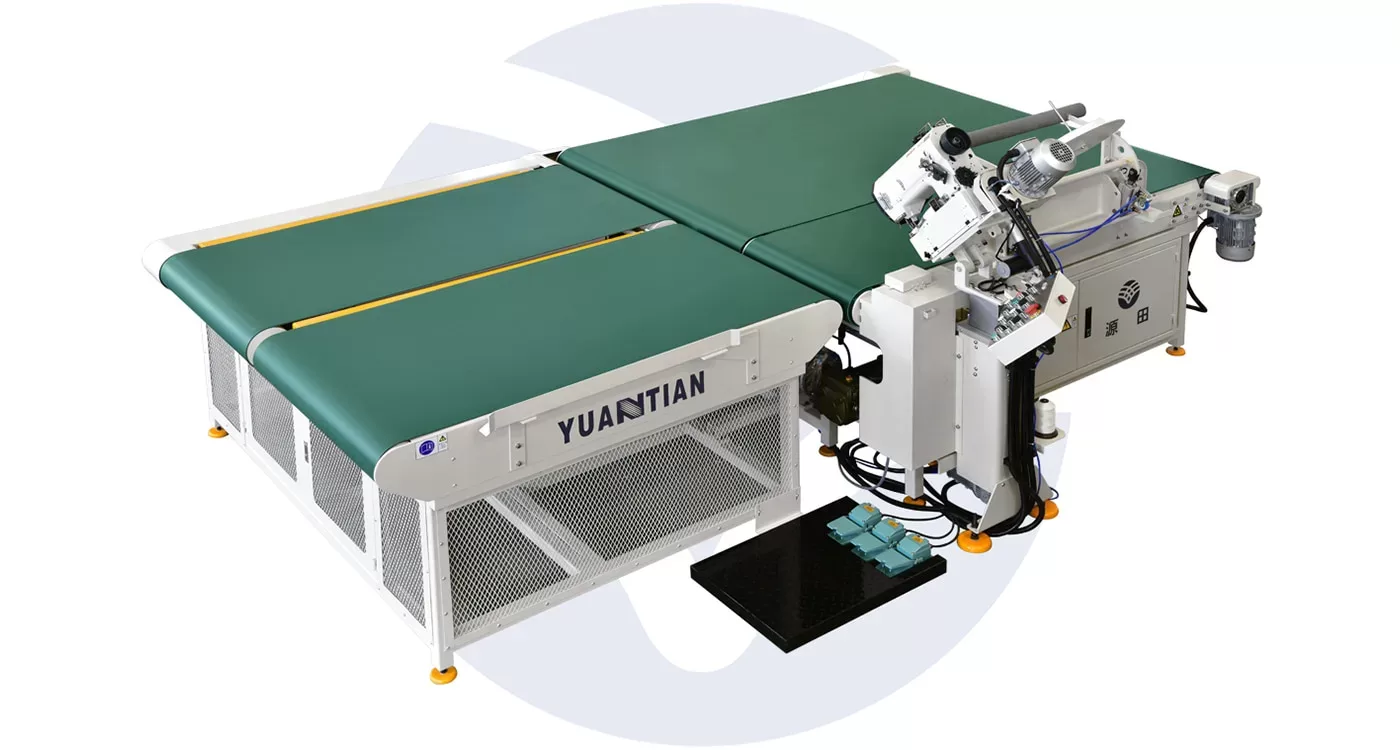

The mattress is usually fed along a conveyor belt, and as it moves on the belt, a sewing head will stitch the tape to the edge. The process is automated and fitted with the required specifications meant for accuracy and precision. Operators can set the machine to whatever size or edge they require at the mattress.

Types of Mattress Tape Edge Machines

Manual Tape Edge Machines

More labor is involved in running a manual tape edge machine. Ideal for small run work or bespoke mattress manufacture where the operator uses the guide line to move the mattress and control the sewing unit.

Features

Operator Control: High level of control over the stitching process.

Flexibility: Easily adjustable for different mattress sizes and styles.

Cost-Effective: Lower initial investment compared to automated machines.

Semi-Automatic Tape Edge Machines

Semi-automatic tape edge machines combine manual guidance with automated stitching, offering a balance between control and efficiency. These machines are ideal for medium-sized production facilities.

Features

Partial Automation: Automated stitching with manual mattress guidance.

Enhanced Productivity: Faster than manual machines with consistent quality.

User-Friendly: Easier to operate than fully manual machines.

Fully Automatic Tape Edge Machines

Fully automatic tape edge machines are machines of high production tier for the high-volume production tier. This machine, with a very minimal operator intervention, enhances productivity to a large degree and also leads to uniform quality for large production runs.

Features

High Efficiency: Capable of producing a large number of mattresses in a short time.

Consistent Quality: Automated processes ensure uniform stitching and finishing.

Advanced Controls: Programmable settings for different mattress types and sizes.

Key Features to Look For

Stitch Quality and Speed

Precisely, the quality of a stitch from a mattress tape edge machine translates directly to durability and how the final product will look. When shopping for a machine with exact stitching to take hold of, the edges should be firmly held in order to bind securely and use attractive bindings.

In addition to that, the speed of the machine is proportional to the production output. Big mattress producers should have high-speed machines, whereas the slower machines will work for numerically smaller rounds of production. Additionally, maintain a balance between speed and quality, which does not undermine the integrity of the mattress.

Adjustability and Flexibility

A good mattress tape edge machine should serve different sizes of beds. The fact that messing around with the settings on the machine can rapidly change from one specification to another indicates high flexibility and, in this instance, high efficiency.

Different mattresses require different styles at their edges. Look for machines that offer flexibility in stitching patterns and edge finishes based on different customer preferences and market requirements.

Durability and Maintenance

Investing in a robust and well-built machine ensures long-term reliability and will have less downtime. High-quality materials and well-built construction enhance the durability of the best machine, which features good value for the worth of your money.

You also need to take into consideration the maintenance needs of the machine. Machines that are easy to service due to components’ easy access and simple servicing procedures help reduce operational downtime and ultimately the lifespan of the machine.

Benefits of Using Mattress Tape Edge Machines

Enhanced Product Quality

Tape edge machines provide mattresses with a final professional and beautiful finish to satisfy customer needs. Neat and firm stitching enhances the appearance, thereby improving the quality of the mattress.

Moreover, well-stitched edges help to hold the mattress materials in place and keep them away from fraying, significantly increasing the mattresses’ lifespan. This kind of durability is critical to customers who want an extended life mattress.

Increased Production Efficiency

Precision enhances the rate and speed of the stitching process. Manufacturers can speed up their volume through the use of fully automated and semi-automatic mattress edge sewing machines with no compromise on the high quality of the final mattress. Efficiency provides exactness and thus could help in meeting up with high-demand periods and large orders.

When manufacturers automate the edge stitching process, they can reduce the cost associated with labor and can, therefore, shift this labor to another part of production. This helps them increase the profitability of the product.

Maintenance and Troubleshooting Tips

Regular Maintenance Practices

Carry out daily checks to assess whether or not the machine has any signs of wear and tear, or even worse, loose components that could affect its performance. Early detection of problems helps prevent costly repairs and downtime.

It is necessary to carry out cleaning and lubrication of the machine on a regular basis in order for it to be in a proper running state. Refer to the manufacturer’s guidelines on the correct cleaning agents and intervals for the best results.

Troubleshooting Common Issues

Stitching Problems: The machine is giving irregular or loose stitches. In such a case, one should look at the tension settings, needle state, and the quality of the thread. Sometimes proper correction or substitution is to be taken with care.

Mechanical Failures: Mechanical failures such as motor failure or conveyor jamming cannot be ignored. If the machine should malfunction, the operator must refer to the machine’s manual for troubleshooting, or contact the manufacturer for troubleshooting or repair advice and support.

Future Trends in Mattress Tape Edge Machines

Integration with Smart Technology

Over time, mattress tape edge machinery will be extended to integrate the IoT and, therefore, permit real-time monitoring and data analysis. With connected machinery, it can report performance metrics and inform types of maintenance or areas where production can be made more efficient.

The introduction of machine learning and artificial intelligence into the equation might, indeed, set up an entirely autonomous machine with an optimal setting, also allowing the machine itself to diagnose its issues and hopefully positively affect productivity with minimal need for any operator intervention.

Sustainable Manufacturing Practices

As sustainability becomes a priority, manufacturers may develop tape edge machines that utilize eco-friendly materials and processes. This shift could reduce the environmental impact of mattress production and appeal to environmentally conscious consumers.

Improved energy efficiency should be expected from future machines to reduce energy use and operation costs. Energy-saving technologies and machine designs will continue to improve to provide good manufacturing practices.

Conclusion

Mattress tape edge machines are essential tools in the production of high-quality mattresses, offering numerous benefits in terms of product quality, efficiency, and durability. Understanding the different types of machines, key features, and maintenance practices is crucial for manufacturers looking to optimize their production processes.

As technology continues to evolve, the integration of smart technologies and sustainable practices will further enhance the capabilities and appeal of these machines. By staying informed about the latest trends and advancements, manufacturers can ensure they remain competitive in the ever-evolving mattress industry.

Связанные с ними товары