Efficient and secure packaging is very important in the mattress manufacturing industry. A mattress packaging machine is a device that is used to first compress the mattress and then pack it so as to reach the client when in an ordered form. The guide describes in detail mattress packaging machines, how they work, type, maintenance, and points to consider in purchasing.

What is a Mattress Packaging Machine?

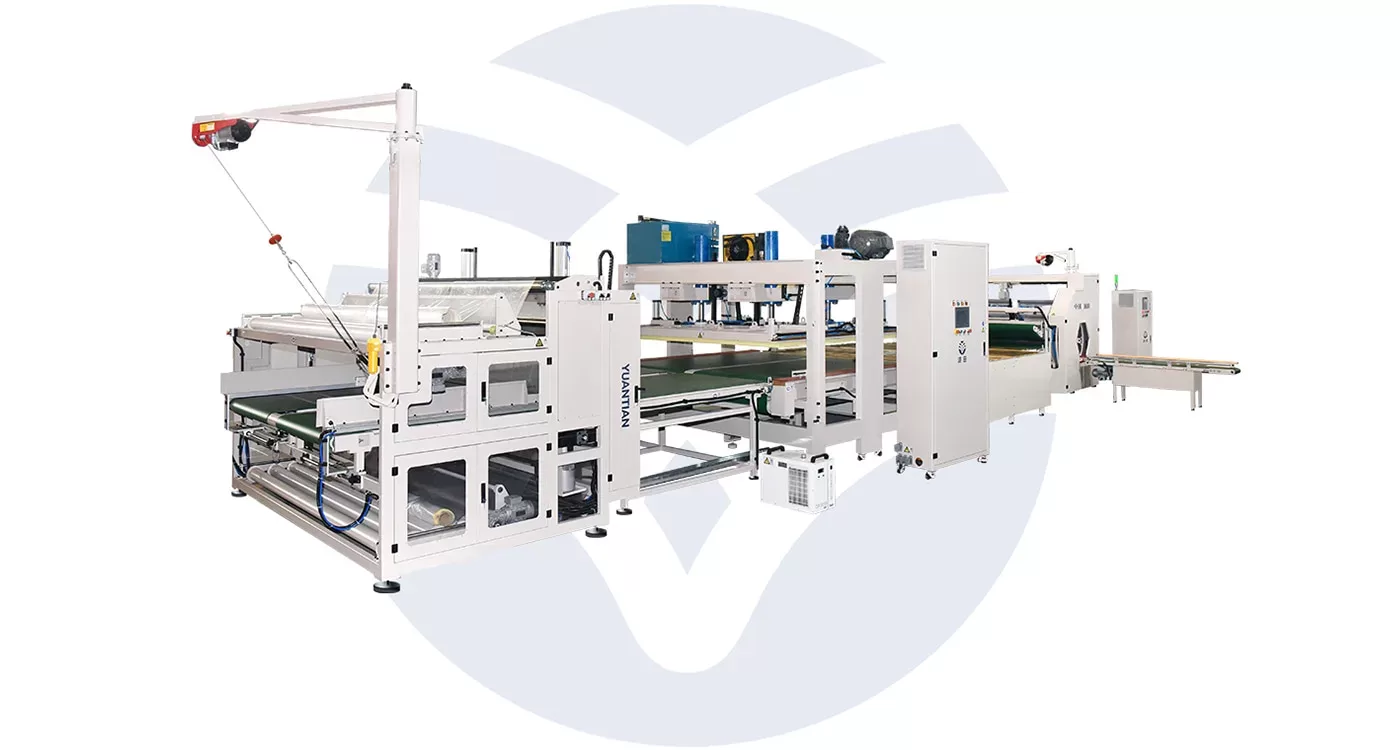

A mattress packaging machine is an industrial machine designed to wrap, compress, and seal mattresses. This makes mattress packaging machines a fundamental and essential packaging tool used to maintain cleanliness, damage, and protect mattresses in a state fit for the customer.

Benefits of Using a Mattress Packaging Machine

Enhanced Protection

One of the main benefits of using a mattress packaging machine is enhanced protection. The packaging machine encloses the mattress with a cover, thus protecting it against dust, dirt, and damage during transportation. This cover ensures that the mattress arrives at its destination in the perfect state it was packed, avoiding any possible compromise in its quality and longevity.

Improved Efficiency

This might increase the efficiency of packaging to a great extent. On the other hand, manufacturers could increase their output and reduce the cost of labor with the automation of the wrappings and sealing process. The automatic packaging machines package several mattresses in less time. These machines are therefore highly imperatively necessary for any business looking forward to higher production by expanding its operation.

Space Saving

Mattress packaging machines are often integrated with a compression feature that minimizes the volume of the mattress. In the process, the number of products that can be packed into a given unit of space increases because the product is compressed. This tends to minimize the cost of storage and shipment in the long run.

Consistency and Quality Control

A machine assures consistency in packaging for every single mattress, maintaining uniform quality across the entire product line. Such consistency is vital to maintaining customer satisfaction and the built-up reputation of the brand, as every customer will be given a product produced in the same excellent quality.

Types of Mattress Packaging Machines

Automatic Mattress Packaging Machines

These are automated machines that carry out packaging with little or no human control. They are efficient for mass use since they are characterized as speedy and efficient. The high speed of the machines ranked them as high-volume handlers, and their features range up to the level of cutting films, sealing, and compression in an automated manner.

Semi-Automatic Mattress Packaging Machines

Semi-automatic machines would need some manual intervention, but these would indeed be a compromise between cost and automation. This could be more apt for medium-scale business. Here an operator would be required to handle mattress placement or packaging initiation, and so on, while the machine could do most of the job.

Manual Mattress Packaging Machines

Manual machines are operated by hand and are best suited for small businesses or startups with lower production volumes. These machines are more affordable but require more labor and time, making them less efficient for larger operations.

Key Features to Consider

Compression Capability

Compression is a vital feature, especially for manufacturers looking to save on shipping and storage costs. Machines with adjustable compression settings offer more flexibility, allowing you to choose the level of compression based on the type of mattress and packaging requirements.

Wrapping Materials

Different machines use different wrapping materials, and some could be made of plastic film while others could be made of fabric. It’s important that you choose a machine that is compatible with the material, but at the same time suits your needs best. Look at factors such as strength, cost, or impacts that the wrapping has on the environment.

Speed and Efficiency

The speed of this machine can highly influence your production process or not. Having taken this into consideration, it will also ensure that mechanisms fit the rate at which you might want to be producing your products. More entrenched devices can boost production line speed and improve any bottleneck that may arise in the same.

Safety Features

Always ensure that machines have some built-in safety features like a stop emergency button, provisional guards, and sensors to avoid accidents. Safety should be the first thing to consider in your operators.

Ease of Maintenance

Choose a machine that can be serviced with spare parts that are easily accessible. Regular servicing of the machine will maintain the operation of the machine while ensuring the durability of the machine.

Customization Options

Some of the machines have personalization features where the wrapping speed, sealing method, and compression rates can be varied. Consequently, such a feature will help you to customize your packaging in the manner in which you want it to be customized to suit your needs.

How to Maintain Your Mattress Packaging Machine

Regular Cleaning

Cleaning the machine ensures increased life and functioning efficiency. The dust and waste that can cause the machine to malfunction are removed regularly. Clean every accessible part, particularly the feed and cut-off points of wrapping material.

Lubrication

All the moving parts should be properly lubricated so that wear and tear is reduced. Follow the recommended types and frequency of lubrication by the manufacturer. Proper lubrication ensures less friction and avoids mechanical failure.

Routine Inspections

Routine inspections help identify problems likely to occur in the packaging process. Parts that seem to be wearing out must be replaced promptly to prevent machine breakdown. Continuous inspection of electrical connections, sensors, and safety features should be carried out to ensure proper functioning.

Calibration

Periodically calibrate the machine to maintain accuracy in wrapping, sealing, and compression. Calibration ensures that the machine operates at its optimal performance, maintaining consistency and quality.

Software Updates

If your machine is equipped with software or digital controls, keep it updated to benefit from the latest features and improvements. Software updates can enhance the machine’s functionality and address any known issues.

Common Problems and Solutions

Wrapping Material Jams

Jams can occur if the wrapping material is not correctly aligned. Ensure the material is loaded properly and check for any obstructions in the machine. Regular maintenance and cleaning can help prevent jams.

Uneven Compression

In case there is uneven compression in the bed, then the machine settings could be incorrect. The user manual usually guides how to do a calibration. Make sure the mattress is arranged correctly about how it should be compressed.

Electrical Issues

The power supply and idle electrical connections should be inspected. Electrical connections should be checked against appropriate safety switches, and blown fuses should be checked as well. Always consult a professional technician if problems persist.

Sealing Problems

Seals that are poor or non-uniform will cause weak seals and, thus, the protectiveness of the mattress may be jeopardized. Therefore, the mechanism should be cleaned and set right. It may need the sealing elements to be replaced if they are worn and also to check the temperature settings.

Software Glitches

If the machine’s software is not functioning correctly, try restarting the system. Ensure all software updates are installed. For persistent issues, contact the manufacturer’s support team for assistance.

Cost Considerations

Initial Investment

This is going to largely depend on the features and the level of automation. First, determine your budget and then look through various machines to see what fits best within that budget. Higher initial costs can be justified by increased efficiency and reduced labor costs.

Maintenance Costs

Also take into account running costs, such as consumables and labor. Sometimes hefting out a little extra for a more expensive, better-built machine can do wonders for your bottom line, as lower long-term maintenance costs more than pay for themselves. Make sure to budget for routine maintenance—the more painless way to prevent surprise repair bills.

Energy Consumption

Equipment with energy efficiency will save you money during operations. Look for energy-saving models with the most modern features that will reduce utility bills. Make a unit based on energy consumption and purchase energy-efficient models.

Training and Installation

For ease and efficiency, some manufacturers can arrange for professional installations and staff training upon purchase.

How to Choose the Right Mattress Packaging Machine

Assess Your Production Needs

Consider your current production volume and what your future growth projections are, since it will assist in making a choice of a machine that caters to your requirements.

Consider Your Budget

Offset the upfront expense with long-term savings. At times, such an invested machine can pay dividends with increased efficiency and a decrease in maintenance.

Read Reviews and Testimonials

As a prospective buyer and a manufacturing company owner, one should research different reviews and testimonials given by other manufacturing companies. This will give a clear perspective on the reliability and performance of the machine.

Future Trends in Mattress Packaging

Automation and AI

The next path could lead to enhanced levels of automation and introduce further artificial intelligence to make the machine smarter and more efficient. They will be able to reduce the process of packaging through the best use of the schedule.

Sustainable Materials

Sustainable materials are the future of packaging. The next path machines might take could be toward newer eco-friendly wrapping options. The way to the future of packaging is in improvements to biodegradable and recyclable materials.

Compact Designs

Part of these lines is soon to be taken up by the compact and versatile packaging ones that are likely to emerge when space becomes a premium for manufacturers, hence expanding their production area to its fullest for extra gain in terms of production. This can compact machine, which is capable of getting into small spaces that can be found in a production area without deteriorating in performance.

Integration with Smart Factory Systems

Connecting a mattress packaging machine to a smart factory system or an IoT device could increase the machine’s functionalities. A data analytic system and real-time monitoring can be executed, consequently optimizing the production process and efficiency.

Customization and Versatility

The future packaging machines will be designed to execute more customization in handling varying mattress types or sizes since the current versatile machines are programmed to produce only a limited number of different mattresses. Versatile machines enable producers to process packing varied requirements, thus granting them maximum flexibility.

Conclusion

Investing in a mattress packaging machine can transform your manufacturing process, offering enhanced protection for your products, improved efficiency, and significant cost savings. By understanding the different types, features, and maintenance requirements, you can choose the right machine to meet your specific needs and ensure a smooth, efficient packaging operation.

Связанные с ними товары