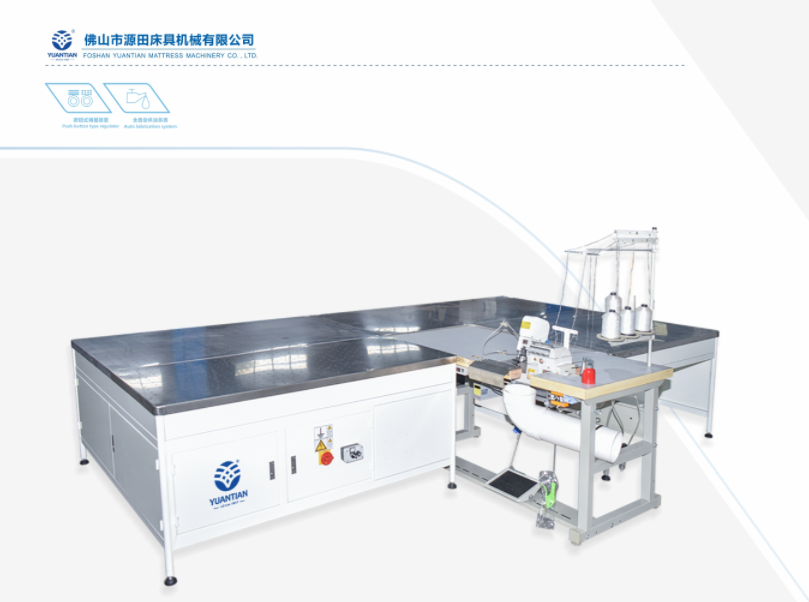

Is sewing thick materials in mattress production difficult? Troublesome machine adjustments, low efficiency, and large space requirements? The new generation star equipment from Yuandian, the “Mattress High-Pressure Foot Overlocking Machine YT-DS-8B,” directly addresses these pain points. It will debut at the German Cologne Exhibition from May 20-23, redefining efficient production with three core technologies.

4.2cm Ultra High-Pressure Foot: Easily Handles Thick Materials, Say Goodbye to Material Jamming The 4.2cm liftable presser foot requires no tools for assistance, directly tackling the sewing of high-density foam and composite fabrics. With sufficient lifting height, the fabric remains wrinkle-free and uninterrupted, eliminating the hassle of traditional manual foot lifting. Even beginners can operate smoothly, significantly improving efficiency per batch.

“Zero Friction” Fabric Movement, Goodbye to Manual Adjustments The new air table creates a floating airflow layer through micro air holes, reducing fabric adhesion. Whether dealing with soft knitted fabrics or stiff non-woven materials, it pushes smoothly without deviation. There’s no need for experience-based friction adjustments; the machine automatically balances fabric movement, saving time, effort, and worry.

One-Button Switching Between Thick and Thin Materials: Multi-Use Machine, Dual Reduction in Space Cost Supports one-button switching between thick and thin mattress material modes, automatically matching parameters such as presser foot pressure and feeding speed for seamless transitions from thick foam to thin knitted fabrics. Say goodbye to multiple machines and manual parameter adjustments; one device covers all scenarios, improving workshop space utilization and reducing labor costs.

Time-Saving, Energy-Saving, Space-Saving: The Value King Debuts

- Efficient: Eliminates machine adjustment time, significantly boosting production efficiency.

- Intelligent: Simple operation, quick onboarding for beginners.

- Flexible: Multi-use machine, eliminating equipment clutter.

Stable performance reduces defect rates and maintenance costs, making it possible to enhance efficiency and reduce costs from large production lines to small and medium-sized factories.

Live demonstrations at the Cologne exhibition will unlock the black technology of mattress overlocking.

From May 20-23, visit Yuandian’s booth (Booth No.: Hall 10.1 G-069G) to witness how the YT-DS-8B effortlessly handles thick material sewing and mode switching. Book now to experience the new intelligent sewing solution that makes every stitch more efficient and precise. We look forward to seeing you at the Cologne exhibition! Simplifying production with technology, empowering manufacturing equipment for production—Yuandian YT-DS-8B, your all-in-one mattress overlocking partner.

[Yuandian Intelligent Manufacturing: 43 Years of Focus on High-Quality Innovation in Mattress Equipment]

Providing global mattress enterprises with integrated intelligent production solutions.

Связанные с ними товары