Efficiency is not just a catchphrase in the high-paced mattress production but a determining factor in beating the competition. With the global market demanding more high-end mattresses, producers have to do everything possible to meet market demands without compromising on quality or profit.

As a leading mattress machinery manufacturer, Yuantian is well aware of the challenge of achieving the ideal balance. Our cutting-edge machines are designed to optimize production lines, enabling factories to make more and waste less time and materials. In this article, we will explore some practical tips to help you maximize the efficiency of your mattress production line.

1. Optimize Your Factory Layout for Seamless Workflow

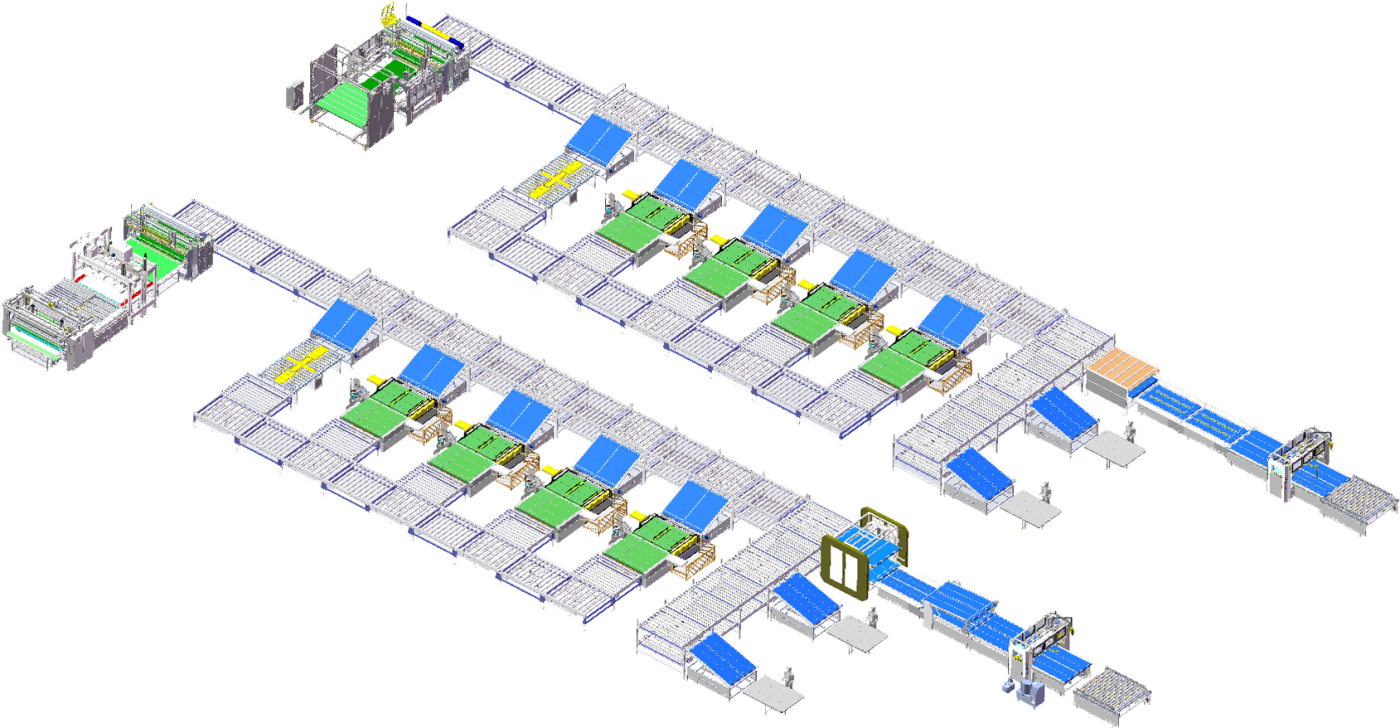

Optimizing the factory plan is the most crucial first step in maximizing productivity. In most mattress production lines, a nonsensical floor plan design would cause the materials and laborers to take unnecessary detours, not only incurring additional transport expenses, but also easily creating bottleneck chains and slowing down the overall rate of production. Mattress manufacturers have to scrutinize their existing processes thoroughly, from the receipt of raw material, cutting, quilting, assembly, to product packaging, and adopt a lean production setup.

For instance, by assuming a U-shaped or linear layout, it can be ensured that material travels in the shortest distance. By positioning the foam cutting machine right next to the quilting operation, the in-between transportation and waiting time can be significantly reduced, and the job can be completed quickly. By doing so, not only is the likelihood of faults lowered, but even the smoothness and steadiness of the overall production can be enhanced.

Yuantian’s modular mattress machinery plays a unique role in layout optimization. They can be flexibly integrated into different factory floor plans and can quickly adjust their positions and functions according to production order volumes or process changes. Modular equipment and logical layout are able to decrease the material moving distance by 20% or more, which indicates that the daily output will be higher directly.

2. Embrace Automation to Reduce Manual Labor Dependencies

Automation has been a game-changer in the mattress sector. In the traditional method, operations like sewing, gluing, and turning over involve enormous manual involvement, not only of which is time-consuming but also open to human mistakes. Investing in automated mattress machines can shift focus away from labor-intensive efforts towards supervision and quality checks, and hence significantly increase output.

High-performance automated equipment have the ability to achieve unprecedented speed and precision. For instance, automatic quilting machines can skillfully work through multi-ply material and complete intricate but repetitive patterns within a few seconds. It is hard to match this efficiency with human effort. Yuantian’s advanced quilting system features high-speed needles and computer-assisted software, and the speed of its processing is far above conventional techniques. In the same way, mattress flipping and stacking machines can assist laborers in eliminating drudgery as well as increase production to a great extent.

To get the most out of automation, add Internet of Things (IoT) sensors for real-time monitoring. These can track machine performance, predict when maintenance is needed, and dynamically adapt operations. Not only does this save downtime, but also makes the most of the service life of the equipment, with the production line always in prime condition.

3. Prioritize Regular Maintenance and Predictive Upkeep

Downtime is inefficiency’s worst enemy. During the mattress production process, if equipment experiences unforeseen failure, it can result in hours or days of downtime, not only in delayed delivery but also in higher maintenance and overtime expenses. It is hence most critical to maintain a good maintenance plan.

Periodic inspection and preventive maintenance are the key to risk reduction. Factories should carry out periodic inspections on all the machinery, and extra attention should be paid to weak points like motors, belts, and cutting blades. Yuantian’s mattress production equipment has advanced built-in diagnostic functions, which give the workers advanced warnings of problems such as abnormal vibration or abnormal temperature. This can help the factory to take preventive measures before the problem becomes severe and avoid surprise shutdowns.

Remember that equipment properly maintained not only survives longer but also operates at peak effectiveness, hence saving energy as well as material.

4. Invest in Comprehensive Employee Training Programs

In the field of mattress manufacturing, even with the most advanced automated equipment, the capabilities and professional knowledge of employees still directly affect production efficiency. Comprehensive training for employees can not only enhance the accuracy of operations, but also significantly reduce error rates and safety risks, thereby ensuring the high-speed and stable operation of the mattress production line.

Formulate a specialized training plan for equipment operation, maintenance, and safety regulations. Through regular practice and training, employees can master the correct operation methods of the equipment, thereby reducing downtime or wear and tear caused by improper operation procedures. At the same time, enhance employees’ safety awareness to prevent personal injury and equipment accidents during operation and maintenance.

Yuantian provides customers with systematic and professional training services to ensure that the equipment can be put into use safely and efficiently. Through training, operators can not only master the equipment characteristics and operation points in the shortest time, but also skillfully apply best practice methods to maximize the performance of the equipment.

5. Implement Robust Quality Control Measures

Efficiency is not only about maximizing output, but also about quality. Without strict quality control, high production speed will eventually lead to more defective products, rework, and even returns, which not only wastes resources but also damages the brand’s reputation. Therefore, quality inspection is carried out at every link in the mattress production line to ensure that high output is achieved without affecting quality.

From fabric cutting and quilting to the layering of sponges and the installation of springs, every process must be strictly controlled. Once any defect is detected, the factory can repair it in time before the problem expands, thus avoiding the scrapping of the entire batch of products and maximizing cost savings.

For instance, visual cameras can be used to check if the stitches are uniform, and sensors can monitor whether the density of the sponge meets the standards, etc. With the help of intelligent detection, mattress manufacturers can ensure high efficiency while guaranteeing that every product meets the highest standards, providing customers with truly reassuring and reliable quality.

Conclusion

Maximizing output in your mattress production line requires a multifaceted strategy. By optimizing layouts, embracing automation, maintaining equipment, training staff, and enforcing quality, manufacturers can further enhance productivity while reducing costs.

In an industry where quality, speed, and customization are critical, a well-optimized production line is the foundation of long-term success. At Yuantian, we’re committed to empowering your success with innovative mattress machinery. Our mattress production lines are engineered for reliability, speed, and scalability, helping you turn efficiency tips into tangible results.

Связанные с ними товары