In the competitive and dynamic bedding industry, the aspect of mattress quality and durability forms very significant variables as regards attraction to consumer interest as well as the overall reputation of the brand among others in the market. One critical component in ensuring these attributes is the use of mattress flanging machines.

The highly competitive machines thus play a great role in the manufacturing process aimed at augmenting superior durability among the mattresses. This passage explains how significant mattress flanging machines are, how they work, and their impact on the overall durability of mattresses.

Understanding Mattress Flanging

Flanging refers to a very important process in mattress making where the border of the mattress is attached to the top and bottom panels of the mattress. This ensures that each layer of the mattress is strongly held together by the act of flanging, which ensures stability and maintains the form of the mattress for a very long time. If not done or achieved properly, the mattress wears out prematurely and includes features like sagging, edge breakdown, and reduced comfort and support.

The Role of Flanging Machines

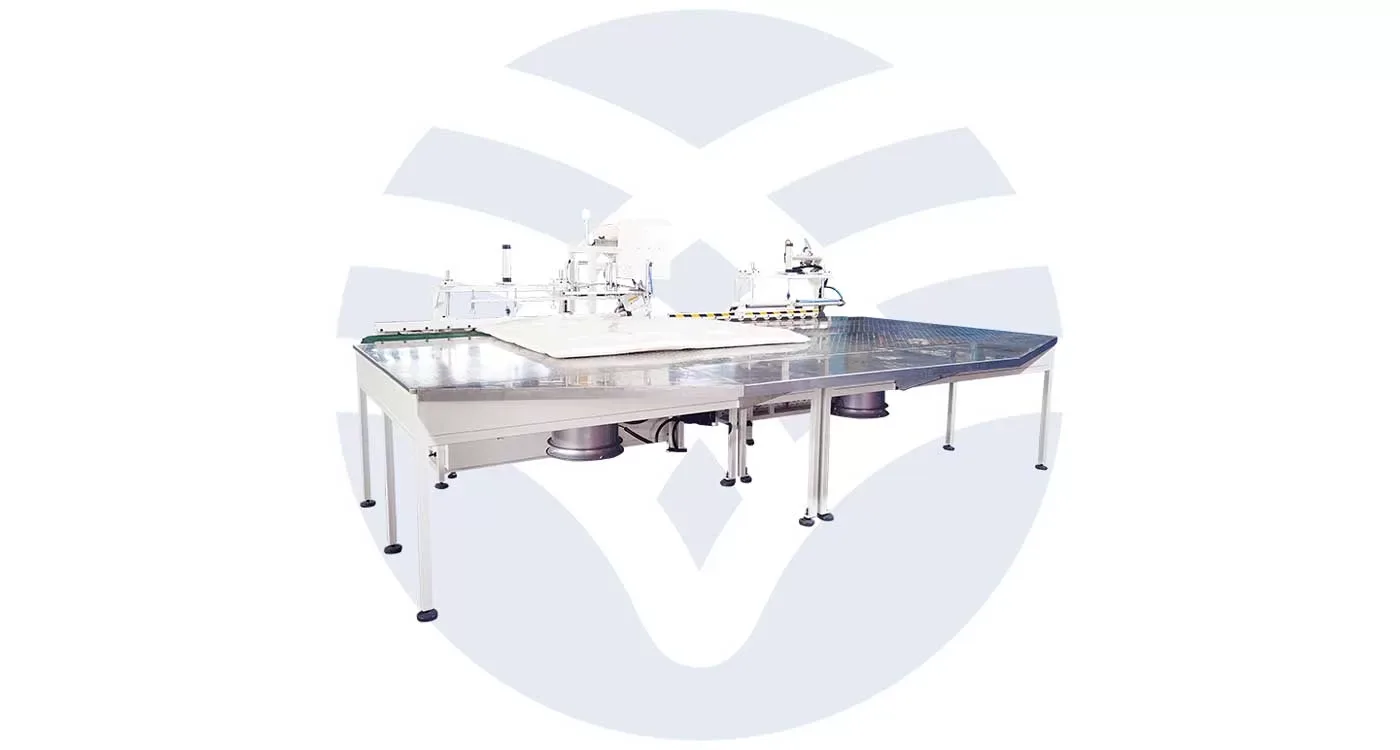

The machines stitch the flanges, which are fabric strips attached to the mattress border, to the top and bottom panels using heavy-duty needles and threads. The stitching should be strong and precise, which will go a long way in running through the years.

Flanging machines are endowed with rather several features to make them perform and function at their level best efficiency, such as computerized controls will make the machine produce patterns for fixing threads accurately. Mattress sizes and thicknesses can be adjusted for in the machine settings.

Automatic material feed, switched-in material quality is assured and the manual workload is considerably reduced. The integration of these features is accomplished through high efficiency and high quality in fast-flow mass mattress production to fit an upsurge in the demand for comfortable, durable products.

Enhancing Durability Through Precision

There is no doubt that one of the big advantages of flanging machines is precision. When done manually, it is okay, and flanging might pave the way for some sort of inconsistency that, eventually, would affect the mattress’s durability. Even the very slightest stitch tension or stitching-alignment inconsistency can lead to weak points that break under stress.

Flanging machines remove all such inconsistencies by ensuring uniform stitching throughout the whole mattress. These use automated control to give precise adjustments, thus placing the right stitch exactly where it should be at the required tension and spacing.

This precision is necessary to hold the support at the edge of the mattress. These are the sections that are usually under high tension, mostly where a human being sits or lies on the mattress. Properly done flanging strengthens the edges so that they do not crumple up or get out of shape. This is enabled by firm and consistent stitch work that ensures the flanging machines resist damage over the long term. The mattress remains stable and durable.

Material Compatibility and Versatility

There is also another advantage of modern technologies: mattresses today have a lot of materials in them—historic innerspring, memory foam, latex, molds, and various types of hybrids, comprising a lot of layers, for better comfort and support. All these materials have peculiarities that may bring some variations to the flanging process.

The advanced flanging machines are designed in such a way that they can conform to the numerous, diverse, and even opposite materials of different thicknesses for them to be able to secure stitching in whatever way the mattress is created.

With such versatility, it enables manufacturers to make a diversity of mattresses without compromising the durability of the machine. This allows such flanging machines to fold large amounts of raw material into proper sheeting, whether the work involves processing dense memory foam or the more flexible latex.

Improve Efficiency and Productivity

With automation through flanging machines, massive efficiency and productivity improvements in the manufacturing process of mattresses are realized. Hand flanging is very labor-intensive and time-consuming, meaning that it does not make it possible to handle a large amount of work by the manufacturing unit of mattresses within a specific period. Contrary to that, automated flanging machines can operate continuously to ensure several units are worked on with minimal human intervention.

The high level of productivity not only assists manufacturers in favor of high demand but also keeps production costs at a minimum. Improvement of work in the flanging process allows companies to divert their workers toward important points of production, such as quality control and innovation.

The result is an efficient assembly line that consists of the best quality, long-lasting mattresses which are delivered to the consumers in a faster and inexpensive manner.

Technological Advancements in Flanging Machines

The latest improvements to mattress flanging machines have been taken up a notch, technologically. For example, there are now those fitted with real-time monitoring and diagnostic features that enable the operator to promptly react to and fix emerging issues. These systems monitor the sewing process with sensors and a camera, ensuring that difference from set parameters is rectified immediately.

Moreover, several advanced models are data-analyzing and process-optimizing, which enables optimization of the flanging process. Intelligent systems learn from performance based on history and automatically transform settings to enhance efficiency and quality constantly. This would mean that manufacturers would keep producing mattresses in the comfort and durability benchmarks that are of high-quality standards.

Environmental and Economic Benefits

Flanging machines are also beneficial in terms of the environment and the economy. Automated flanging, therefore, helps in reducing material waste, once the cutting is already accurate and lacks faults. Such effectiveness saves resources and has an environmental advantage during the process of making up mattresses too.

In addition, the long life of mattresses made with the help of flanging machines means that fewer mattresses end up in landfills, making the bedding industry more sustainable.

It means economic value for the product, as a customer can be more satisfied and loyal if the mattress serves him or her longer. Consumers are more willing to buy a mattress if they know that it will serve their purpose over the long term. This confidence in the product easily turns into repeated business and positive testimonials for any brand.

Conclusion

In the modern bed industry, flanging machines for mattresses are considered to be the machines of the highest importance. They are the ones that guarantee mattress life and durability. This flanging process provides mattresses with improved structural stability due to its automation and the bond of precision, repeatability, and flexibility in delivering great resistance against mechanical loads.

As the bedding industry continues to evolve, the importance of durable, high-quality mattresses cannot be overstated. Mattress flanging machines will remain at the forefront of this evolution, ensuring that manufacturers can meet the demands of a discerning market while maintaining the highest standards of product excellence. In doing so, they not only revolutionize mattress production but also contribute to a more sustainable and economically viable industry.

Связанные с ними товары