What is tape edge machine? Tape edge machine is a special sewing machine used in mattress manufacturing. It is mainly used to sew the top and bottom panels of the mattress together with the frame or tape.

Tape edge machine plays a vital role in mattress manufacturing. Why say that? This is due to the fact that it can satisfy consumer demand for customized and diversified products while simultaneously increasing the productivity and quality of mattress production.

There are many benefits to using a tape edge machine in mattress manufacturing. For example, improves production efficiency and product quality. This is important for mattress manufacturers because it can improve their competitiveness in the market.

In this article, we will provide you with a comprehensive guide to tape edge machines, including how they work, machine types, advantages, maintenance and future trends.

Basic Understanding of Tape Edge Machines

A basic understanding of tape edge machines can help mattress manufacturers make better use of these machines and gain more advantages (such as improving production efficiency, product quality, reducing costs, etc.) in the production process to maintain a competitive advantage in the market.

Below, we will give you a basic understanding of the tape edge machine from two aspects: the main components of the tape edge machine and its working principle.

Main Components of Tape Edge Machines

1. Sewing Head

One of the machine’s most crucial components is the sewing head. It is mostly used to sew the border or tape together with the top and bottom panels by stitching around the borders of the mattress.

The height and angle of the sewing head are both able to be adjusted. Because of its adaptability, the machine can be made to fit the specific needs of consumers by fitting mattresses of various sizes and types.

2. Sewing Table

During the sewing operation, the sewing table offers a steady moving surface as the sewing head must travel along the edge of the mattress. This guarantees that the sewing head moves precisely around the mattress’s edge to finish the sewing job.

The sewing table’s flat surface ensures that the mattress remains flat while sewing and prevents twisted or skewed seams around the mattress’s edges.

3. Movement System

When sewing mattresses, the motion system is in charge of directing the sewing head’s movement around the edge of the mattress to guarantee that the thread and needle are sewn in the proper directions.

Powered by electricity or pneumatics, the motion mechanism makes sure the sewing head goes steadily and properly around the mattress.

These drive systems are very accurate and dependable, and they can accurately control the sewing head’s movement trajectory to guarantee high-quality and productive stitching.

4. Control Panel

The control panel is a key component of the tape edge machine and plays the core role in operating the machine.

There are usually start and stop buttons on the control panel that the operator can press to start and stop the operation of the machine.

There are usually various buttons, knobs, or touch screens on the control panel for adjusting various settings (such as sewing speed, thread density, etc.) of the machine. Operators can adjust these settings as needed to meet the production needs of different mattresses.

How Tape Edge Machines Work?

During the mattress manufacturing process, the border or tape is sewed to the top plate and bottom panels using a tape edge machine. We shall go over the tape edge machine’s operation in detail below:

The mattress is first set up on a work table by the operator of the tape edge machine. Ensuring that the mattress’s edges line up with the sideband or border is crucial. Why? Because inaccurate alignment could lead to uneven edges or shoddy stitching.

Second, the operator can modify the sewing speed, sewing tension, seam location, and other parameters of the tape edge machine based on the dimensions and features of the mattress to attain the intended outcome.

The sewing head then revolves around the mattress’s perimeter to stitch the tape or border to the top and bottom panels once the tape edge machine has been turned on.

Ultimately, the mattress is taken out of the machine once the stitching is finished. To ensure that the stitches are tidy and firm, the operator will check them.

Functions of Tape Edge Machines

In the mattress manufacturing industry, tape edge machines are crucial. This is because they have a variety of functions that can greatly improve production efficiency and product quality.

Automatic Edging

The automatic edging feature of the tape edge machine is made possible by a precise sewing head and moving mechanism. To finish the edging procedure, the sewing head can move along the edge of the mattress while the needle and thread are threaded through its panels and borders.

All the operator needs to do is set the mattress on the machine, turn it on, and then walk away. The machine will take care of the edging on its own without assistance. This significantly lowers operating issues and labor expenses.

This automated function lowers the chance of human error while increasing efficiency. By guaranteeing the uniformity and quality of the edging on each mattress, automatic edging raises the overall standard of the product.

Efficient Production

The efficient production function of tape edge machines is reflected in many aspects.

First of all, the tape edge machine’s automated operation significantly lowers labor expenses and boosts output effectiveness. All that is needed for the machine to perform the edging duty automatically is for the operator to establish its parameters, no manual labor is needed.

Secondly, automation features can finish numerous mattresses’ edges rapidly, increasing production efficiency.

In order to better accommodate different mattress kinds and sizes, the tape edge machine can additionally adjust the edging’s linear density and speed. This increases production flexibility and efficiency.

In general, the manufacturing function of the tape edge machine is efficient, which enables mattress makers to meet market demand by producing more high-quality mattresses more quickly.

Strong Adaptability

Tape edge machines are available in different lengths, widths, and thicknesses to accommodate different mattress sizes (e.g. single mattress, king-size mattress, etc.).

There are also various stitching technologies to choose from, such as single-sided, double-sided, and four-sided stitching technologies to meet the needs of different types of customers.

Due to its strong adaptability, the tape edge machine can meet the needs of a wide range of consumers and a variety of mattresses.

Quality Assurance

One of the main functions of tape edge machines is quality control. So how is quality control carried out? Mainly through their sophisticated sewing head and control system. They can make the sewing lines regular and even, ensuring that each mattress has perfect edging quality.

In addition, modern tape edge machines have automated control and detection systems that can monitor the machine’s condition and stitching quality in real time. In this way, problems can be discovered and acted upon promptly to ensure edge quality.

Types of Tape Edge Machines

The mattress manufacturing industry uses a variety of tape edge machines, each with unique features and functions. The three primary kinds of tape edge machines are as follows:

Manual Tape Edge Machine

A manual tape edge machine requires manual operation. It requires more personnel and operational knowledge than the automatic tape edge machine.

Although manual operation may increase some labor costs and production time, in some cases, manual tape edge machines still have certain advantages and applicability.

For instance, the cost of investment for manual tape edge machines is not very high, which is more attractive for some small or startup mattress manufacturers.

In addition, manual operation offers the operator more control flexibility as manual tape edge machines can be adjusted according to specific requirements.

However, in terms of production efficiency, manual tape edge machines are less effective than automated ones. There is no doubt about this, because manual operation is definitely not as fast as automatic operation.

Therefore, for some small or special needs mattress manufacturers, manual tape edge machine is a good choice. However, if you want high production efficiency, then automatic tape edge machines may be more suitable.

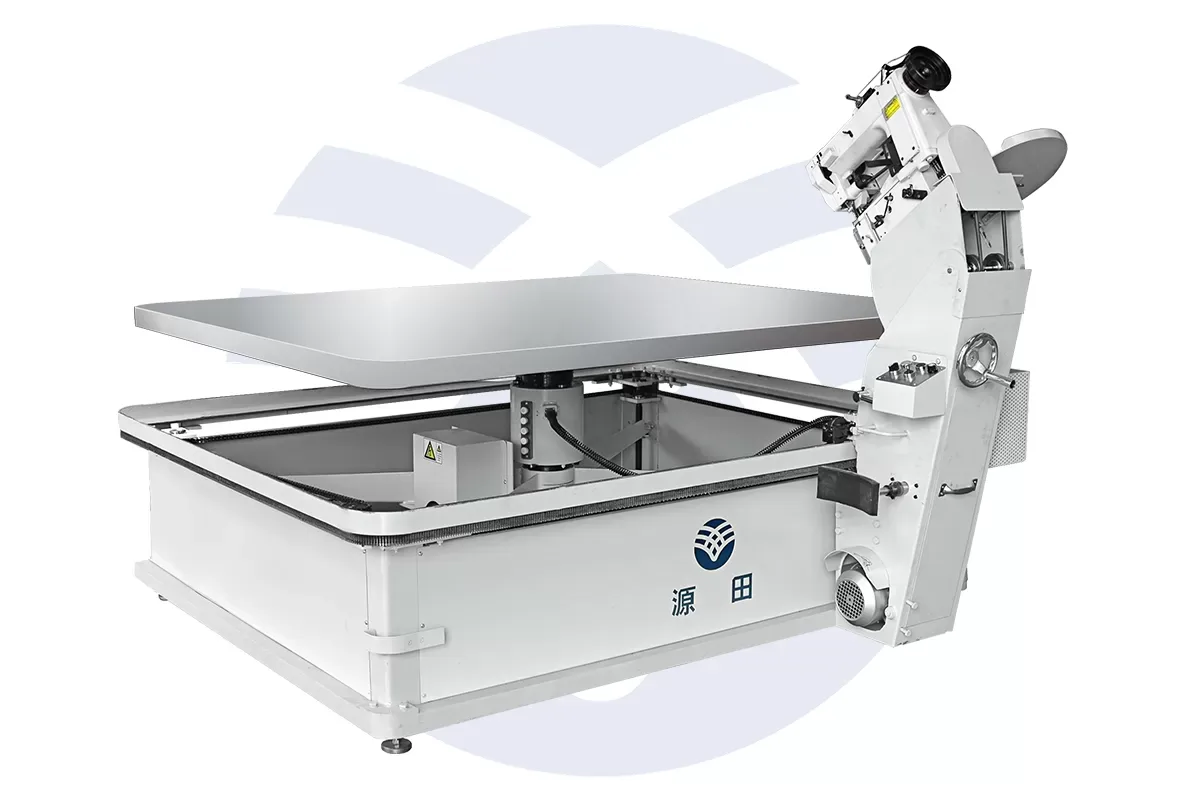

Semi-Automatic Tape Edge Machine

A semi-automatic tape edge machine combines the benefits of both manual and automatic operation. In addition to being more productive than the automatic tape edge machine, it is also more affordable than the manual machine.

Although semi-automatic tape edge machines have automatic movement and stitching capabilities, operators still have to perform some manual controls, such as changing stitching speed, thread density, and other settings.

They can handle a greater variety of mattress sizes and types due to their semi-automated design. Semi-automatic tape edge machines are a suitable choice for small and medium-sized mattress manufacturers.

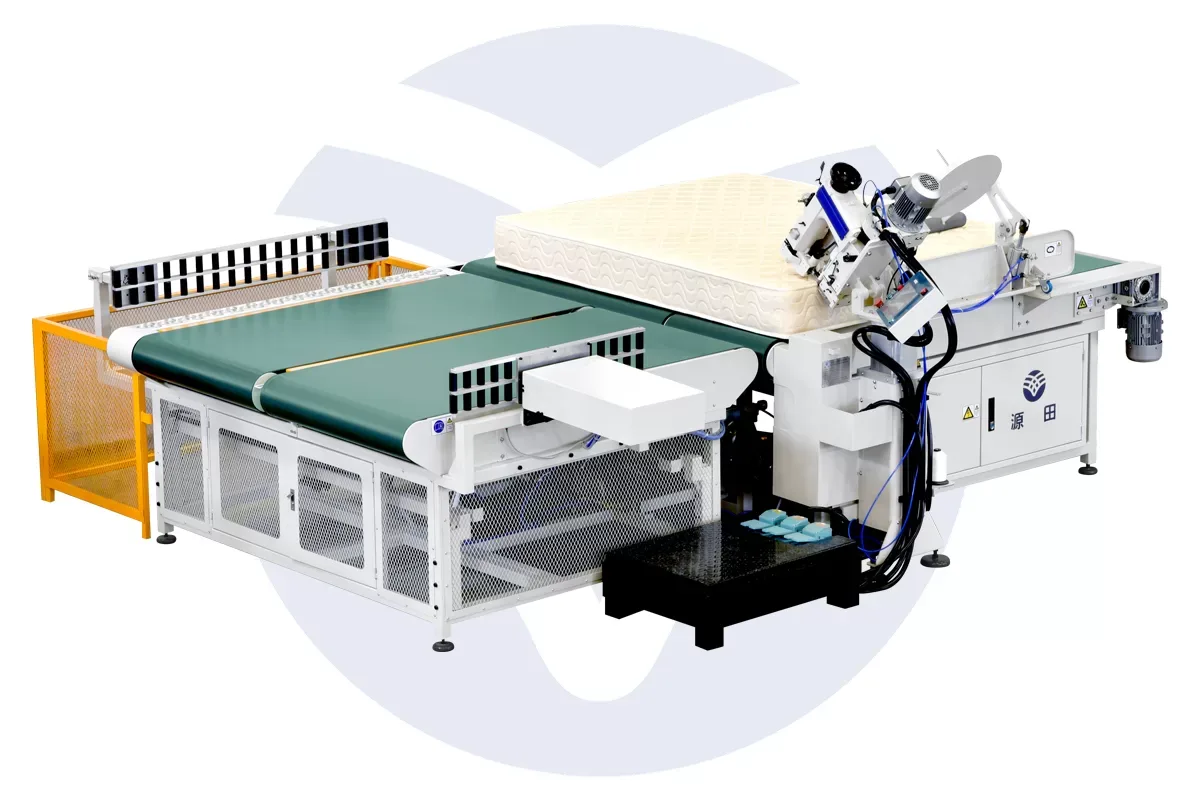

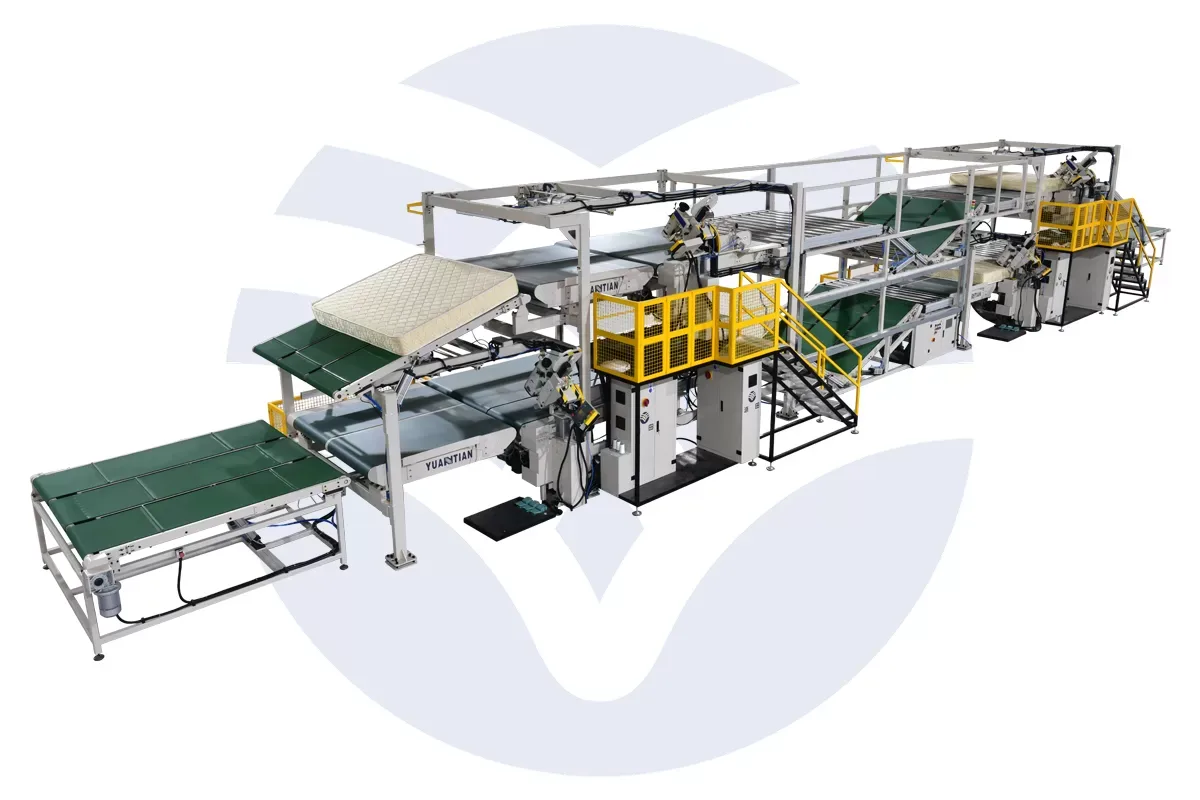

Automatic Tape Edge Machine

Although the purchase cost of automatic tape edge machines is higher than manual or semi-automatic equipment, the level of automation and production efficiency are very high.

Automatic tape edge machines use advanced control systems and sensors to automate stitching and moving tasks. The operator only needs to place the mattress on the machine, set the parameters, and the machine will automatically sew.

Furthermore, they can automatically adjust the stitching speed, thread density, and other factors based on the size and kind of mattress to ensure the uniformity and quality of the edging of every mattress.

Because of the high production efficiency of automatic tape edge machines, they can quickly edge a large number of mattresses. This is important for mattress manufacturers as it helps them have a good competitive advantage in the market.

At the same time, compared to manual and semi-automatic machines, the edging quality of automatic tape edge machine stitching is more consistent and reliable, better meeting the demands of producing mattresses of superior quality.

Maintenance of Tape Edge Machines

The key to maintaining mattress tape edge machines can be divided into three aspects: regular cleaning, regular lubrication, and regular inspection. Each aspect is explained in detail below:

Regular Cleaning

Through regular cleaning, you can keep the tape edge machine in good condition, ensure its normal operation, and extend its service life. It’s best to clean it regularly based on frequency of use to avoid dust and dirt buildup, which can affect the machine’s performance.

Use a soft cloth and detergent to clean the machine. Be careful to use a detergent suitable for the material of the machine to avoid damage to the machine.

In addition, when cleaning, be careful to avoid moisture entering the inside of the machine, so as not to affect the normal operation of the machine.

Regular Lubrication

Regularly lubricating the moving parts (such as bearings, slide rails, etc.) of the tape edge machine can reduce wear and extend the service life of the machine and ensure the normal operation of the machine.

A few things to note when lubricating your machine. First, choose the appropriate lubricant according to the machine manufacturer’s recommendations, which can effectively protect the critical components of the machine.

Secondly, it is usually recommended to lubricate every once in a while to ensure the normal operation of the machine. Also, be careful not to over-lubricate. Otherwise, the lubricant may overflow and contaminate the machine or the working environment.

By the way, before lubrication, make sure the surface of the lubrication part is clean to avoid dust and impurities from entering the inside of the machine.

Regular Inspection

By regularly checking the working status of each component of the belt edge machine, problems can be discovered and dealt with in time to avoid machine failures that affect production.

Inspections such as checking electrical components, transmission components, sewing heads, etc. to ensure they are in good working order.

For example, for transmission components, check whether belts, chains, gears, etc. are loose, worn or damaged to ensure the normal operation of the transmission system.

By correctly maintaining the tape edge machine, you can extend its service life, improve production efficiency, and ensure product quality. Therefore, mattress manufacturers should make a reasonable maintenance plan and strictly implement it to ensure the good operating condition of the machine.

The Future Development Trend of Tape Edge Machines

As a key equipment in the mattress manufacturing industry, the tape edge machine’s future development trends are mainly reflected in the following aspects:

More Intelligent

With the development of technology, tape edge machines are becoming more and more intelligent. In what aspects is it reflected? For example, by adding more intelligent technologies (such as sensors, automatic control systems, etc.), the tape edge machine can monitor and adjust the working status more intelligently.

Take smart sensors as an example. They can not only monitor sewing quality and speed in real time, but also automatically adjust sewing parameters. This intelligent technology not only improves production efficiency, but also reduces the possibility of human error and improves the overall quality of the mattress.

Increased Automation

In the future, tape edge machines will achieve a higher degree of automation. There is no doubt about this. The machine will have more automated functions, such as automatic thread changing, automatic adjustment of sewing parameters, automatic recognition of mattress size, etc.

The tape edge machine can automatically adjust the stitching path and thread density according to the size and requirements of the mattress without manual intervention. This greatly improves the efficiency and consistency of production.

This automated development direction allows mattress manufacturers to respond to market demand more quickly and produce mattress products that better meet consumer needs.

Multifunctional Features

The mattress market needs are constantly changing, so tape edge machines also need to have more functions to adapt to the edging needs of different products.

Versatility includes being able to accommodate different sizes and types of mattresses (including single, double, crib, etc.), sewing different borders and tapes (cotton, polyester, etc.), achieving different edging styles, and more.

By having more functions, tape edge machines can meet the market’s demand for different mattress products, improving the adaptability and flexibility of the machine.

In this way, mattress manufacturers can flexibly adjust the design and production of mattresses according to market demand.

Conclusion

In summary, this guide comprehensively explores various aspects of tape edge machines, covering their working principles, machine types, functions, maintenance, and future trends.

Tape edge machines play an important role in mattress manufacturing. They can improve production efficiency, ensure product quality and save costs. At the same time, they also can enhance the competitiveness of mattress manufacturers in the market.

As technology continues to progress, tape edge machines will also continue to develop. The development of tape edge machines is primarily focused on automation and intelligence, which will enhance product quality and manufacturing efficiency.

A thorough understanding of tape edge machines is crucial for mattress manufacturers. This enables them to make better use of this essential machinery and achieve greater success in the market.

Связанные с ними товары