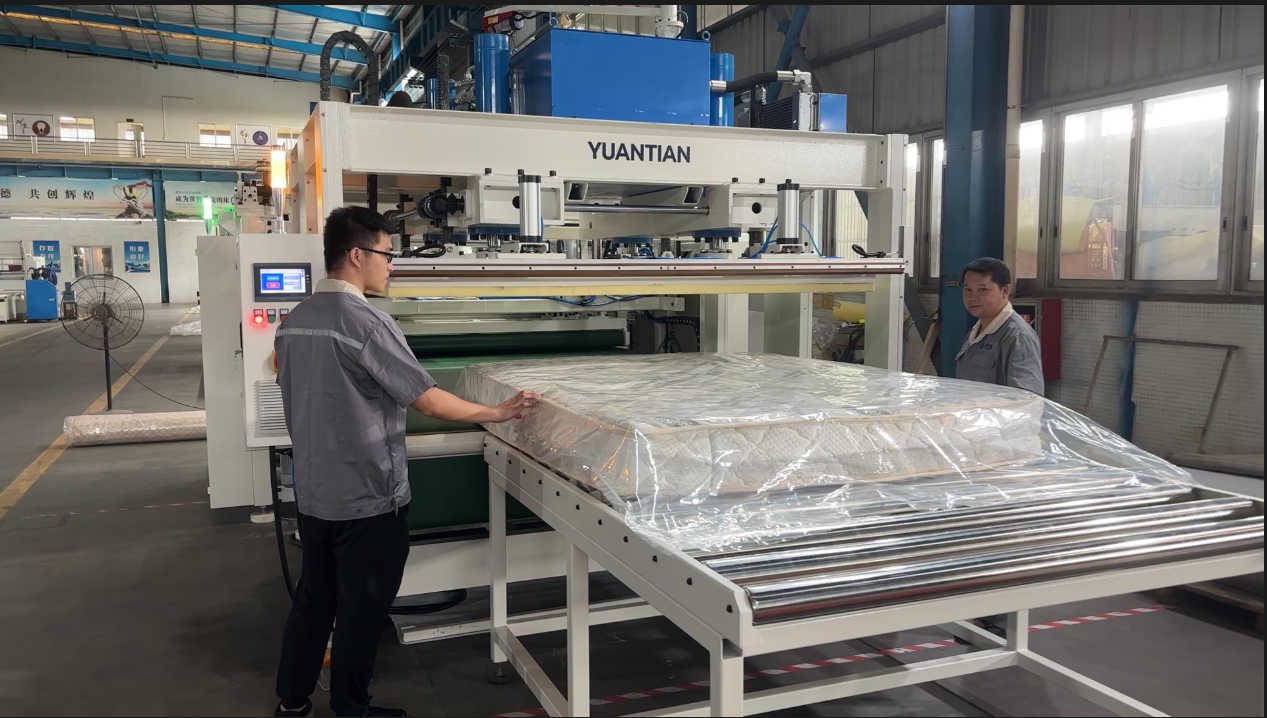

On the road of pursuing efficient production and excellent quality, Yuantian semi-automatic mattress roll packaging machine YT-BZ-6B is undoubtedly the star product of this week. It not only integrates advanced technology and design, but also fully considers the diverse needs of customers. Here are the four key highlights of the model:

Efficient use of space

The YT-BZ-6B covers an area of only 7080*3600*3800 mm, which greatly optimizes the layout of the production line, helps customers effectively save space, improve production efficiency, and adapt to different scale production environments.

Advanced servo control system

The whole machine adopts servo control system to ensure stable and efficient operation. The electrical components are selected from Schneider, Omron, Lanbao, Chint and other internationally renowned brands, the cylinder adopts AirTAC, the servo system is INVT, and the reducer is selected Qiangzhu and Quansheng to ensure the long-term stable operation of the equipment.

Technical advantages of flexible placement

YT-BZ-6B adopts a modular design concept, and customers can freely combine and configure various components according to actual needs, and flexibly respond to changing market needs. This customized solution fully demonstrates the flexibility and adaptability of intelligent manufacturing, helping customers quickly respond to market changes.

A wide range of mattress sizes

· It is suitable for independent pocket spring mattresses, sponge mattresses, latex mattresses and other types to meet diversified production needs.

· It can handle mattress thickness of 80-450mm, length up to 2130mm, width up to 1930mm, wide range of applications.

· Equipped with a 100-ton hydraulic system, it ensures that the compression needs of all roll mattresses are met.

· The reel assembly adopts servo control, and the diameter of the finished product is adjustable from 200 to 550mm, and the fastest reel efficiency is 25-35 seconds per sheet, which greatly improves the production efficiency.

Связанные с ними товары