Evolution of Pocket Spring Machines

When we first hear the term pocket spring mattress, the question that comes to mind is: what exactly is a pocket spring mattress? Pocket spring mattresses are made up of specific springs that are encased in their own material and padded compartments to nourish your body and prevent “rolling together”. In other words, it is a unique, expensive and luxurious typical hybrid mattress, it is a single-sided foam cover model with pocket coils and memory foam sheets, a protection in latex in a sewn zip cover cut in the middle. Sounds fun, right? It is really hard to produce these pocket spring mattresses from the aspects of techniques requiring more mattress making machine to co-work and various technical instruments. When Yuantian produces such pocket spring mattresses, we require the design team to develop the outline about what materials and features the pocket spring mattress should have and whether can hold back bacterials as well as offer comfortable sleeping experience for sleepers or not, all the processing can’t be stated in a word, If you want to know which machine is perfect for making pocket spring mattresses, read on.

Pocket spring mattresses have gained immense popularity due to their superior comfort and support. These mattresses are composed of individual springs encased in fabric pockets, enabling each spring to work independently and provide targeted support to different areas of the body. The manufacturing process of pocket spring mattresses has undergone significant evolution over the years, with the advent of specialized machinery and automation. The production of pocket spring mattresses has evolved from traditional manual techniques to advanced automated systems. In the early days, craftsmen manually coiled the springs and stitched the fabric pockets, resulting in time-consuming and labor-intensive processes. However, as technology progressed, dedicated machines were developed to streamline and enhance the manufacturing process.

The first significant innovation was the introduction of spring coiling machines, which automated the process of shaping the wire into individual coils. These machines offered precise control over the coil dimensions, improving consistency and quality. As a result, manufacturers could produce springs of uniform size and shape, ensuring a more reliable and comfortable mattress. Subsequent advancements led to the development of pocket forming machines, which mechanized the creation of fabric pockets. These machines could fold, stitch, and cut the fabric strips with great speed and accuracy. The automation of pocket formation eliminated human error and improved the efficiency of the manufacturing process. Additionally, the introduction of specialized stitching mechanisms and high-speed sewing machines further enhanced the durability and strength of the fabric pockets.

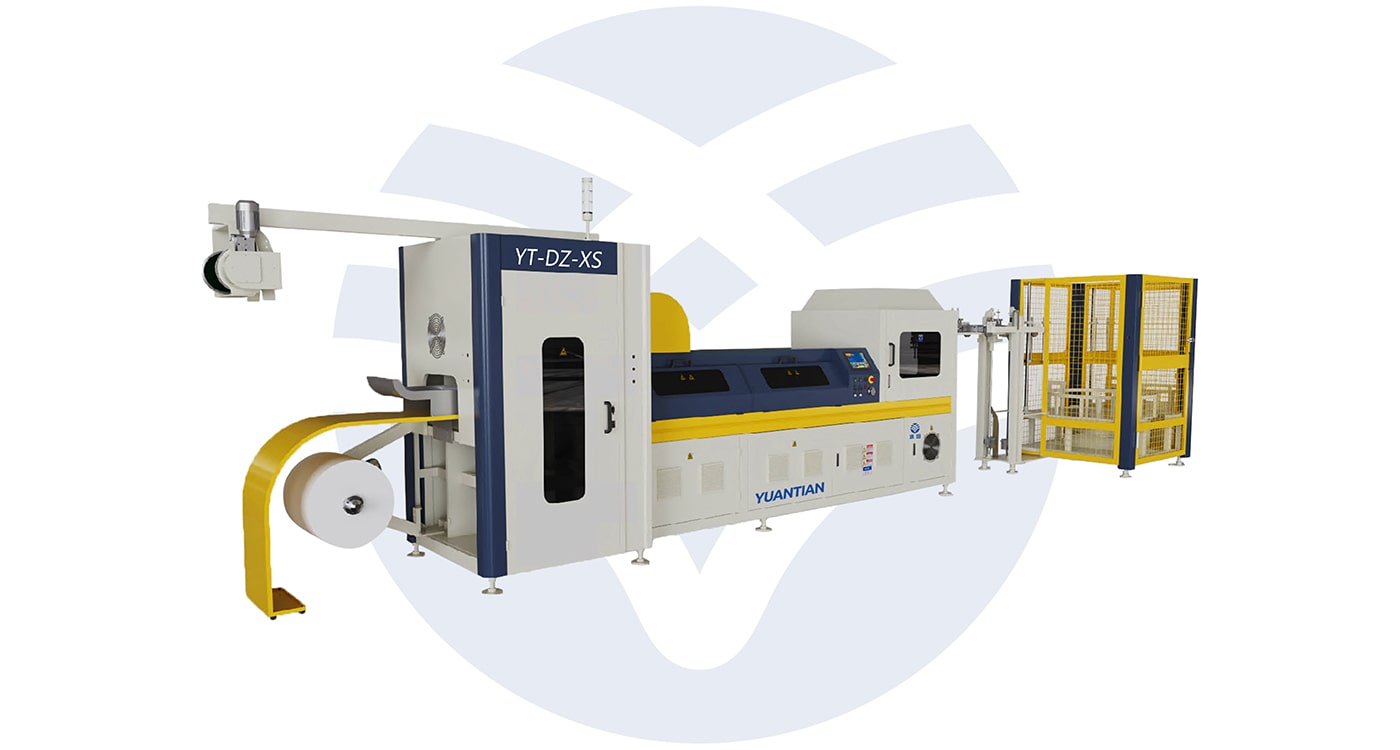

Yuantian pocket spring machines are available in various configurations and levels of automation, ranging from manual operations to fully automated systems. The choice of machine depends on the production volume, desired level of efficiency, and specific requirements of the mattress manufacturer. Yuantian pocket spring machine is a type of manufacturing equipment used in the production of pocket spring mattresses. Pocket spring mattresses are made up of individual springs encased in fabric pockets, allowing each spring to work independently and provide targeted support to different areas of the body. The pocket spring machine automates the process of creating these fabric pockets and inserting the springs into them.

The Manufacturing Process of Pocket Spring Machine

-

Wire preparation: High-quality steel wire is obtained and undergoes a preparation stage. This may involve cleaning, lubricating, and annealing (heat treatment) processes to enhance the wire’s properties and make it more malleable.

-

Coiling the springs: The prepared wire is fed into a coiling machine, where it is formed into individual springs. The coiling machine rotates the wire, shapes it into a coil, and cuts it to the desired length. The diameter, height, and number of turns of the coils can be adjusted to meet the mattress’s specifications.

-

Fabric cutting: Fabric sheets are prepared by cutting them into strips of the appropriate width and length. The fabric used for the pockets is typically a strong and durable material, such as non-woven or woven fabric.

-

Pocket forming: The cut fabric strips are then processed to form pockets for the individual springs. The fabric is folded in half lengthwise, and the edges are stitched or glued together to create a tube-like structure. The fabric strip is then cut into individual pocket-sized lengths, leaving one end open.

-

Spring insertion: The formed fabric pockets are positioned on a conveyor or assembly line. The individual springs are mechanically inserted into the open ends of the fabric pockets. This can be done using robotic arms, mechanical mechanisms, or a combination of both.

-

Pocket sealing: Once the springs are inserted, the open ends of the fabric pockets are sealed to secure the springs in place. The sealing process can involve stitching, heat-sealing, or adhesive methods. The goal is to ensure that the springs remain securely encased within the fabric pockets.

-

Assembly and joining: After the pocket springs are sealed, they are arranged in a specific pattern and joined together to create the mattress core. This can involve aligning and attaching the individual pocket spring units to each other using stitching, glue, or other joining techniques.

-

Comfort layers and mattress construction: The pocket spring core is typically combined with additional comfort layers, such as foam, latex, or fiber padding, to enhance comfort and support. These layers are added on top of the pocket spring core and may be attached or quilted together using specialized machinery.

-

Border and quilt panel attachment: The mattress border and quilted panel are attached to the core and comfort layers. The border provides structural support and defines the mattress’s edges, while the quilted panel adds an aesthetically pleasing finish to the mattress’s top surface.

-

Finishing touches: The finished mattress undergoes a final inspection for quality control, ensuring that all components are properly aligned, attached, and finished. The mattress is compressed, rolled, or packaged according to the manufacturer’s specifications for shipping and storage.

These machines have revolutionized the mattress industry by allowing manufacturers to produce high-quality mattresses with superior comfort and support. The individual pocket springs enable better contouring to the body’s shape, reduce motion transfer between sleep partners, and provide targeted support to different pressure points.

Pocket Spring Machine Enhances Working Efficiency

Pocket spring machines have significantly enhanced working efficiency in the manufacturing process. The integration of advanced technology and automation has revolutionized the production of pocket spring mattresses, leading to several benefits and improvements. Pocket spring mattress machines are designed to operate at high speeds, significantly increasing production rates. The automation of various stages, such as spring coiling, fabric cutting, pocket forming, and spring insertion, eliminates manual labor and accelerates the overall process. The machines can produce a larger number of mattresses in a shorter time, meeting the demands of the market more efficiently.

Manual processes are prone to human error and inconsistencies. However, pocket spring machines ensure precise and consistent results. The use of automated mechanisms and robotics guarantees accurate alignment and placement of springs within the fabric pockets. This level of precision enhances the quality and comfort of the final mattresses, leading to greater customer satisfaction. The automation of various manufacturing stages reduces the need for extensive manual labor. Pocket spring machines can perform tasks that previously required a significant workforce. This reduction in labor requirements not only lowers production costs but also allows manufacturers to allocate human resources to other essential areas of the production process, such as quality control and product development.

From other aspects, Pocket spring machines incorporate quality control mechanisms to detect and address any defects or inconsistencies in the manufacturing process. These machines can perform real-time checks, ensuring that the springs are properly inserted, fabric pockets are securely sealed, and the overall mattress construction meets the desired standards. By detecting and rectifying issues early on, the machines minimize the production of defective mattresses, saving time and resources. Moreover, Modern pocket spring machines offer customization options to meet the diverse preferences of customers. Manufacturers can easily adjust the parameters of the machines, such as coil diameter, height, and number of turns, to create mattresses with specific comfort and support levels. This flexibility allows manufacturers to cater to a wide range of market demands efficiently.

Pocket spring machines enable a streamlined workflow, minimizing bottlenecks and optimizing the overall production process. The integration of various machines into a cohesive system ensures smooth material flow, reducing waiting times and maximizing operational efficiency. Manufacturers can better plan and schedule production, optimizing resource utilization and meeting tight deadlines effectively. The precise control and automation offered by pocket spring machines minimize material waste. Accurate cutting of fabric strips and controlled coiling of springs ensure minimal scrap or excess material. Manufacturers can optimize material usage, reducing costs and contributing to a more sustainable manufacturing process.

The Impact of Pocket Spring Machines On Mattress Design

Pocket spring machines have had a profound impact on the design and construction of modern mattresses. With their advanced technology and automation, these machines have revolutionized the way mattresses are manufactured, leading to enhanced comfort, support, and durabilit. For one thing, it provides superior support and pressure relief in mattresses. The individual springs encased in fabric pockets work independently, allowing them to respond to the body’s contours and provide targeted support to different areas. The precision and consistency of pocket spring machines ensure that each spring is properly aligned and placed within the mattress, resulting in optimal spinal alignment and reducing pressure points.

The customization options offered by pocket spring machines further contribute to improved support. Manufacturers can adjust the coil diameter, height, and number of turns to meet specific comfort requirements. This flexibility allows for the creation of mattresses that cater to different body types and sleeping preferences, ensuring a more personalized sleep experience. Furthermore, Pocket spring machines play a significant role in enhancing the durability and longevity of mattresses. The precision of these machines ensures that the springs are uniformly formed and properly inserted into fabric pockets, eliminating the risk of premature wear or sagging. The use of high-quality steel wire and durable fabric materials further contributes to the longevity of the mattress.

Yuantian Pocket Spring Machine To Customer

At Yuantian, we understand the importance of precision and efficiency in mattress manufacturing. Our pocket spring machines are engineered to provide unparalleled accuracy and speed, ensuring consistent quality and productivity. With state-of-the-art automation and robotic systems, our machines precisely coil and insert springs into fabric pockets with minimal human intervention. This eliminates errors, reduces labor costs, and boosts overall efficiency, allowing you to meet high production demands without compromising on quality.

We recognize that every customer has unique requirements when it comes to mattress design. With Yuantian pocket spring machines, you have the flexibility to customize your mattresses to meet diverse market demands. Our machines offer adjustable parameters such as coil diameter, height, and number of turns, enabling you to create mattresses with specific comfort levels and support. Whether you need a firm mattress for back support or a plush mattress for luxurious comfort, our machines empower you to cater to your customers’ preferences. The individually encased springs work independently, contouring to the body’s shape and providing targeted support where it’s needed most. This promotes proper spinal alignment and reduces pressure points, allowing your customers to enjoy a restful and rejuvenating sleep experience. With our machines, you can create mattresses that deliver the perfect balance of comfort and support, ensuring customer satisfaction and loyalty.

Investing in Yuantian pocket spring machines means investing in the longevity and durability of your mattresses. Our machines ensure uniform and precise spring formation, resulting in mattresses that withstand the test of time. By using high-quality steel wire and durable fabric materials, our machines create pocket spring mattresses that resist sagging, maintain their shape, and provide lasting support. With the ability to produce mattresses with higher coil counts, our machines distribute weight evenly, minimizing the risk of premature wear and ensuring a longer lifespan for your products. Yuantian pocket spring machines are your gateway to revolutionizing mattress manufacturing. With our commitment to precision, efficiency, customization, durability, and comfort, we offer you the tools to elevate your products and exceed customer expectations. By investing in our advanced pocket spring machines, you will experience enhanced productivity, improved quality control, and the ability to create mattresses tailored to your customers’ needs.

Связанные с ними товары