In the realm of mattress manufacturing, precision and efficiency are paramount. Modern mattress tape edge machines represent a significant technological advancement that has revolutionized the process of finishing mattresses with tailored edges. These machines automate and streamline the intricate task of sewing fabric edges around mattresses, ensuring a seamless finish and consistent quality. This comprehensive exploration delves into the features, benefits, and impact of modern mattress tape edge machines in the industry.

The Evolution of Mattress Tape Edge Machines

The evolution of making mattresses in respect of automation and machinery is one real process within the history of the same. Mattress edge processing is integrated into the entire mattress manufacturing process, but manual sewing requires a lot of labor while still giving inconsistent results.

This is when the tape edge machines were introduced for a very radical turn towards a mechanized and automated approach to production. In this new birth, several evolutions within these machines, advancements, and integrations of advanced technologies, of course, are brought in to enhance, even more, efficiency, versatility, and precision.

What is a Mattress Tape Edge Machine?

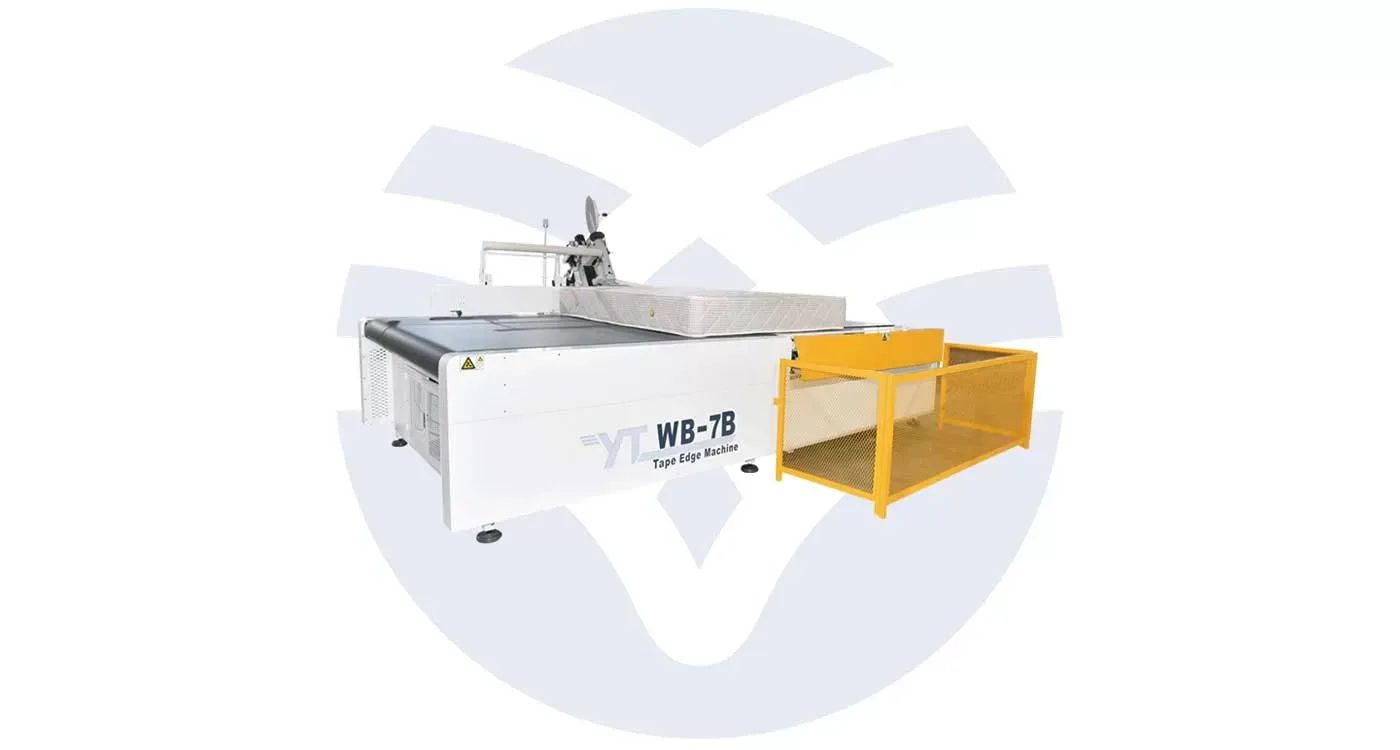

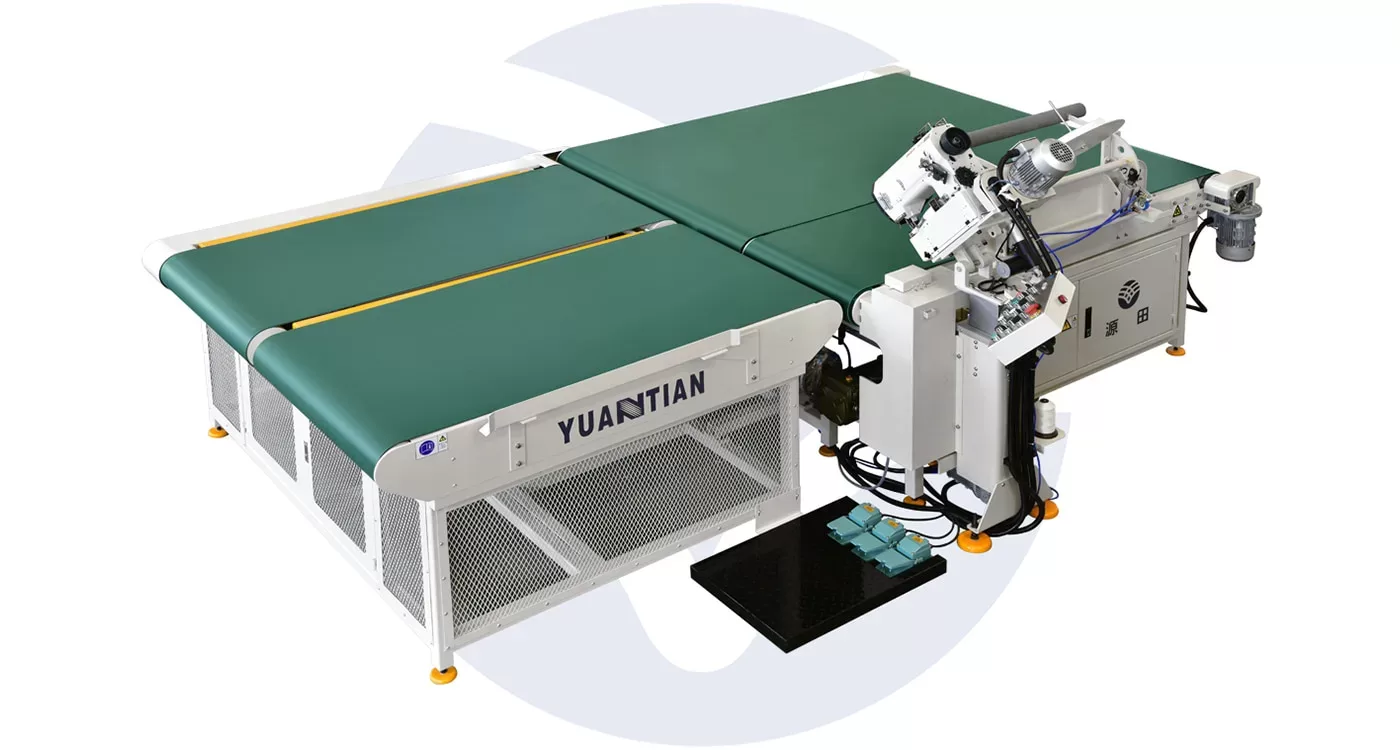

A mattress tape edge machine is an automatic, specially designed machine that sews fabric edges around mattresses. Generally, such machines come with a good combination of multiple sewing heads, a conveyor system, and many other adjustable platforms, to accept mattresses of different sizes and thicknesses. The main operation of a tape edge machine is folding and sewing folded fabric panels or “tapes” on a mattress around the border section to give it a neat finish.

Key Features of Modern Mattress Tape Edge Machines

Multiple Sewing Heads

Current tape edge machines have multiple heads. Most companies provide tape edge machines with heads ranging from two to six or more heads. The provided multiple sewing heads sew concurrently, and the top and bottom tapes fold in on the edge of mattresses giving rise to efficiency and consistency in stitching.

Adjustable Sewing Speed

For dictating different mattress sizes and the demand of production, tape edge machines come with variable sewing speeds. The operator can adjust the speeds for the best quality of stitches and optimal productivity in relation to different production demands.

Conveyor System

It conveys the mattress during the edge sewing process. The conveyor is adjustable both in length and width to different sizes and thicknesses of the mattresses, thereby ensuring every smooth and precise position of sewing.

Automatic Corner Cutting and Taping

The current range of tape edge machines is equipped with automatic corner-cutting and taping mechanisms. These features allow for efficient and accurate cutting of excess fabric at mattress corners, along with the perfect taping of fabric tapes, which liberates the operator from trimming work and also saves on material wastage.

Programmable Controls and Touchscreen Interface

The advanced tape edge machine has all the programmable controls and a user-friendly touchscreen interface. One can easily program stitching patterns, calibrate settings, and control the operation with real-time machine performance tracking. This user interface results in better operational efficiency and less setup time for different kinds of models of mattresses.

Precision Stitching and Edge Alignment

This dedicated precision in finishing the edges of a mattress counted much on the support lent to good looks. Modern tape edge machines feature advanced sensors and stable mechanisms that achieve precision in stitching and edge alignment to minimize throughput problems.

Durability and Reliability

Today, tape edge machinery is built of good material and with adequate components to provide durability and reliability in the most demanding manufacturing environments. It is proven to work uninterruptedly under heavy working conditions or loads and to operate over extended periods very often, without very little downtime.

Safety Features

To ensure operator safety, tape edge machines are equipped with various safety features such as emergency stop buttons, safety guards, and automated shutdown systems in case of malfunctions or anomalies.

Advantages of Modern Mattress Tape Edge Machines

Enhanced Efficiency and Productivity

The most important advantage of the modern tape border machines is that their efficiency and productivity are very high indeed. They automate labor-intensive work connected to the mattress process, thus reducing the dependence on labor and quickening the manufacturing cycles. Manufacturers can work at higher rates of output and meet tight deadlines without compromising quality.

Consistent Quality and Precision

Modern tape edge machines provide quality and accuracy in mattress edge closing. Eliminating the human factor from the sewing process, the machines offer equally stitched mattresses with beds that are well-tailored. Consistent quality enhances the product’s appeal and longevity, modalities that have a direct impact on customer satisfaction and brand reputation.

Cost Efficiency

Although a big capital investment is needed during the initial establishment, a modern tape edge machine can prove to be a long-term, cost-effective investment. Automation eliminates the labor costs related to sewing an edge manually, reduces the material waste that results from defective cutting and sewing, and decreases productive inefficiency. A high ROI can be recognized from a rise in productivity and a reduction in operational costs.

Versatility in Production

Modern tape edge machines are versatile and amenable to mattress sizes, types, and the volume of production. With inherent versatility, the machine settings can be adjusted to fit within wide-ranging mattress specifications without the need for extensive reconfiguration. This flexibility allows for improvements in the flexibility and scalability of production, enabling manufactories to respond readily to market demand and custom orders.

Improved Workplace Safety

Modern tape edge machines enhance workplace safety because they are automated devices that are otherwise physically demanding while doing an otherwise repetitive mattress edge-sewing task. The operator is much less exposed to the risks associated with the manual handling, cutting, and sewing of large-sized mattresses and fabrics. Further safety measures continuously reduce the risks of occurrence of accidents and injuries in the workplace, which makes the workplace safer.

Conclusion

Modern mattress tape edge machines play a pivotal role in the mattress manufacturing industry by automating the intricate task of edge sewing, ensuring precise and consistent quality in mattress finishing. These machines enhance efficiency, productivity, and operational flexibility while reducing labor costs and material waste. With advanced features such as multiple sewing heads, adjustable settings, and user-friendly interfaces, tape edge machines enable manufacturers to meet diverse production requirements and customer demands effectively.

As the industry evolves, mattress manufacturers continue to innovate to meet changing market demands and provide high-quality mattresses that meet the expectations of consumers around the world. Modern mattress tape edge machines represent a cornerstone of efficient and sustainable mattress manufacturing, supporting industry growth, innovation, and excellence in product quality and customer satisfaction.

Связанные с ними товары