In the mattress manufacturing industry, efficiency and cost control are the two most crucial factors determining profitability. As global demand for premium mattresses continues to grow, manufacturers are increasingly relying on automation to keep pace. The automatic mattress packing machine is a remarkable innovation in this field, aiming to simplify the solution in the final stage of production. But before investing, businesses must understand their costs and benefits.

Understanding the Role of an Automatic Mattress Packing Machine

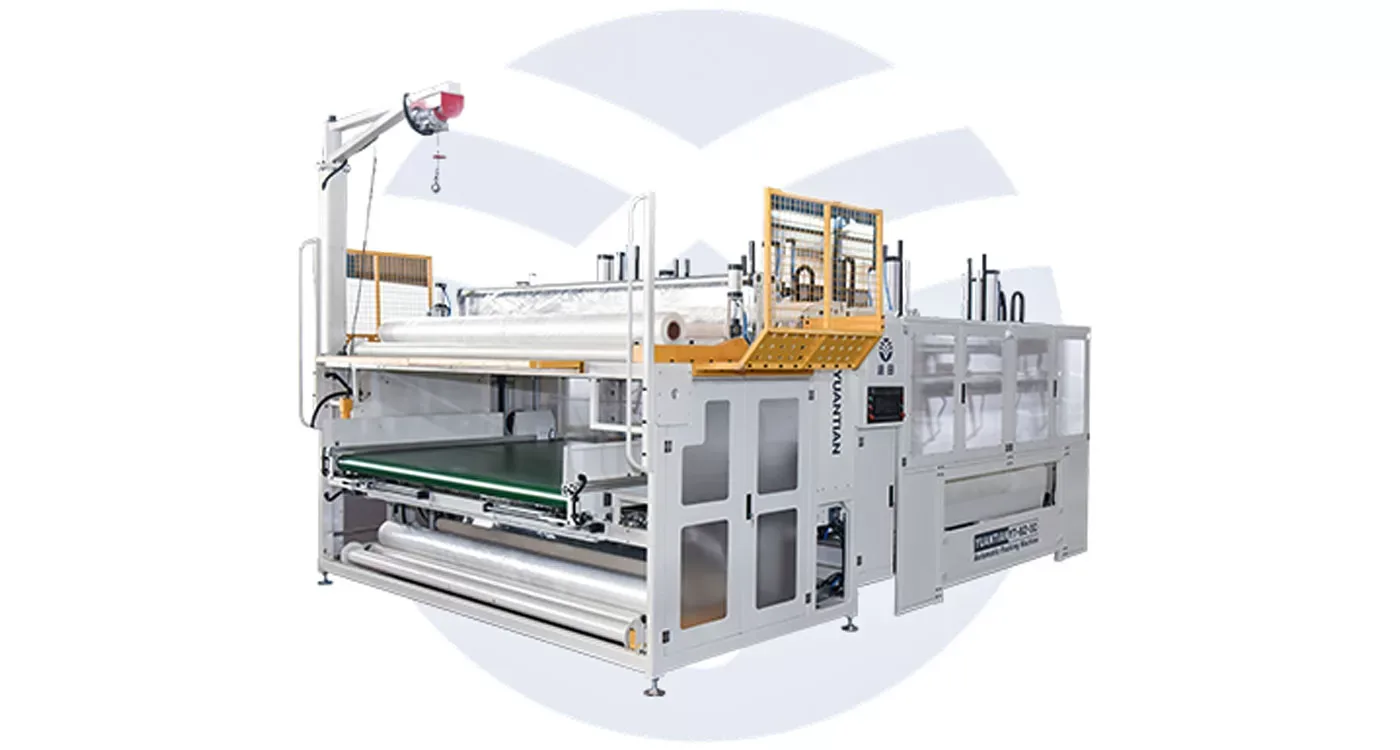

The function of the automatic mattress packing machine is to compress, roll, seal, and package mattresses in a convenient way for storage, transportation, and distribution. This automation reduces manual labor significantly and improves consistency in package quality.

By successfully compressing the mattress, its volume can be significantly reduced, thereby saving transportation and storage costs. The vacuum sealing aspect, on the other hand, protects the product from dust and moisture. Furthermore, its automatic feeding and output functions enable continuous production.

Cost Considerations

In deciding to invest in an automatic mattress packing machine, the initial step is to list clearly the investment cost. The investment cost includes initial purchase cost, installation and setup cost, and maintenance cost.

Initial Purchase Price

Automatic mattress packing machines vary in complexity, degree of automation, and production efficiency, resulting in significant price differences. The lower models are cheaper with fewer features, and they are ideal for small-scale production enterprises with low production volumes and single product categories.

Mid-to-high-end packaging machines have higher levels of automation, higher capacity, flexibility for various mattress specifications, and even smart detection and data management. Such machines are a gigantic investment, but can significantly improve production efficiency and reduce manual operation.

Installation and Setup

Proper installation can ensure the optimal performance and safety of the packaging equipment. The costs in this regard may include site preparation, electrical adjustments, and integration with existing production lines.

For instance, if it is incorporated with the current production line, the production process and system connection may need to be redesigned. This may have additional software programming and mechanical debugging costs.

Maintenance and Repairs

No matter how advanced or high-quality a machine may be, it cannot be completely immune to normal wear and tear over time. To be able to guarantee optimum performance of the mattress packing machine, regular maintenance is inevitable. Lubrication, replacement of worn parts, and occasional maintenance and repair should all be included in long-term costs.

By establishing reasonable maintenance and repair cycles and troubleshooting and repairing potential problems in advance, the possibility of costly repairs can be largely avoided. Preventive maintenance is less expensive than interim repair and enables companies to achieve higher reliability and competitiveness in business.

Benefits of Investing in Automation

The advantages of an automatic mattress packing machine extend well beyond labor savings but also include increasing production efficiency, protecting products, facilitating logistics, and improving customer satisfaction.

Increased Production Speed

The automatic mattress packing machine has an incredible speed advantage. The manual packing process generally requires multiple individuals to work together on moving, bagging, sealing, and sorting in sequence. Each mattress may take a few minutes. Not only is labor intensity great, but also the packaging quality will definitely be affected by inconsistent operation.

Automated packing equipment can complete the entire process of mattress compression, rolling, and packaging in seconds, which enhances efficiency by multiple or even tens of times. This kind of speed advantage allows the manufacturer to process more orders within the same production time, alleviate production pressure, and most importantly, ensure stable output capacity even during peak sales season.

Labor Cost Reduction

The automatic mattress packing machine can take over repetitive and time-consuming packaging tasks such as handling, compression, bagging and sealing, which can reduce the number of workers required for packaging and ultimately lower direct labor costs.

At the same time, the widespread labor shortage problem faced by the manufacturing industry has also been alleviated. Enterprises no longer need to invest a large amount of resources in recruiting and retaining skilled workers, thus allowing their limited human resources to be concentrated in more value-added links, such as quality inspection or production optimization.

Consistency and Quality Control

Manual operation is inevitably affected by fatigue, level of experience, and operation habit, thus resulting in uneven compression, poor sealing, or inconsistent tightness of packaging. This not only affects the product’s appearance, but also likely results in damage during transportation.

The automatic packing machine, with precise mechanical control and preset parameters, achieves a consistent compression ratio, sealing temperature, and pressure for each package, ensuring all products meet the same standard. This reinforces brand reliability and reduces the risk of returns due to packaging issues.

Space-Saving in Storage and Shipping

After being compressed and rolled, the mattress only occupies one-third or even less of its initial space, so that the warehouse is able to store more products in the same area. During transportation, with the reduction in volume, more products can be loaded on each container, truck, or shelf, significantly reducing the cost of transportation per product.

This not only reduces warehousing and logistics costs, but also minimizes loading and unloading times, contributing to the operational efficiency of the supply chain as a whole. For manufacturers that need to export or ship from region to region, the space savings translate directly into increased profits and more competitive pricing models.

Improved Product Protection

Automated sealing technology can provide mattresses with comprehensive protective packaging, excluding entirely dust, dirt, moisture, and even friction and compression during transportation. It is particularly required for high-quality mattresses or high-hygiene requirement products.

Through the use of proper packaging techniques, the integrity of the package and the seal quality are guaranteed, with minimal chances of damage or contamination during extended shipment or long storage. Ultimately, the mattresses received by customers can remain clean and in good condition as they were when they left the factory, thereby enhancing customer satisfaction and brand reputation.

ROI and Payback Period

Return on investment (ROI) is one of the most important indicators for determining the economic returns of an automatic mattress packing machine. It intuitively reflects the degree of balance between the benefits and costs generated by the investment. It not only depends on the labor, cost, and time of logistics saved, but also on the incremental revenue generated as a result of increased capacity of production capacity and uniformity in quality.

The payback period on it indicates the time when the initial investment is recovered. In a highly competitive manufacturing industry, the shorter the payback period, the faster the capital turnover and the less risk involved. Through cost-benefit analysis, companies are able to calculate more accurately the ROI and payback period and thus scientifically plan investments and production so as to realize the highest equipment value.

Conclusion

The automatic mattress packing machine can help in the long run to deliver cost savings, higher efficiency, and higher customer satisfaction. For big mattress manufacturers, the benefits far outweigh the cost, leading to a relatively short payback period. Small businesses, however, need to be careful to calculate ROI as accurately as possible, consider leasing, or begin semi-automatic systems before opting for full automation.

Ultimately, decisions should be based on a comprehensive cost-benefit analysis and take into account current production demands, growth forecasts and market competition. In industries where operational efficiency directly affects profitability, the right investment in automation is a decisive factor for long-term success.

Связанные с ними товары